Choosing the right PPR brass fitting for your plumbing or industrial project is essential for ensuring a durable and efficient system. With numerous options available, understanding the key factors can make the selection process straightforward and effective. Let’s explore everything you need to know to make an informed choice.

What Are PPR Brass Fittings?

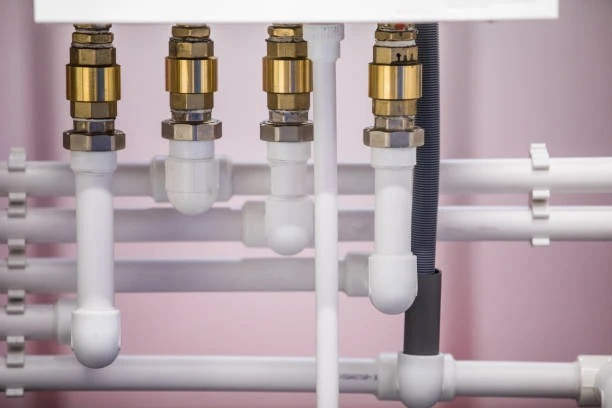

PPR (Polypropylene Random Copolymer) brass fittings combine the strength and durability of brass with the reliability of PPR piping systems. These fittings are widely used in plumbing and heating systems, offering excellent thermal resistance and long-lasting performance.

Key Benefits of PPR Brass Fittings

- Durability: Brass components resist corrosion, ensuring long-term use.

- Thermal Stability: Suitable for both hot and cold water systems.

- Pressure Handling: Capable of withstanding high-pressure environments.

- Compatibility: Designed to seamlessly integrate with PPR pipes.

Why Choosing the Right PPR Brass Fitting Matters

Selecting the appropriate fittings can:

- Prevent leaks and system failures.

- Maximize the efficiency of your plumbing system.

- Reduce long-term maintenance costs.

Factors to Consider When Choosing PPR Brass Fittings

- Type of Application

- Residential setups require cost-effective and easy-to-install fittings.

- Industrial projects may demand high-performance, durable fittings.

- Material Quality

- Ensure the brass used is free from lead and impurities.

- Pipe Compatibility

- Match the fittings to your PPR pipes’ dimensions and specifications.

Types of PPR Brass Fittings

- Elbows: Useful for changing the direction of a pipeline.

- Tees: Allow for branching connections.

- Couplings: Join two sections of PPR pipes.

- Valves: Manage and control the flow of water or fluids.

Understanding Brass Quality in PPR Fittings

High-quality brass offers several advantages:

- Excellent resistance to corrosion and rust.

- Superior strength compared to other metals.

- Long lifespan, even under challenging conditions.

Comparing PPR Brass Fittings with Alternatives

While plastic-only fittings may be cheaper, they lack the durability and temperature tolerance of brass. Similarly, steel fittings can corrode over time, making brass the optimal choice for most applications.

How to Inspect PPR Brass Fittings Before Purchase

- Visual Inspection

- Look for visible cracks, dents, or imperfections.

- Certifications

- Verify compliance with industry standards.

- Durability Testing

- Confirm the fittings’ ability to handle high pressure and temperatures.

Common Mistakes When Choosing PPR Brass Fittings

- Ignoring Pipe Compatibility

- Mismatched sizes can lead to leaks.

- Selecting Low-Grade Materials

- Inferior brass compromises system integrity.

- Overlooking Installation Requirements

- Not all fittings suit every application.

How Proper Fitting Selection Prevents Common Issues

Using high-quality, compatible fittings reduces the risk of:

- Leaks

- System inefficiencies

- Frequent repairs and replacements

Innovations in PPR Brass Fittings

The market continues to evolve with:

- Lead-Free Fittings: Enhancing safety for drinking water systems.

- Eco-Friendly Options: Using recyclable materials to minimize environmental impact.

Consulting Professionals for PPR Brass Fittings

Professional plumbers or engineers offer valuable insights into:

- Choosing fittings for specific project requirements.

- Ensuring adherence to local plumbing regulations.

Maintenance Tips for PPR Brass Fittings

- Regular Inspection

- Check for signs of wear or corrosion.

- Cleaning

- Prevent buildup that can affect performance.

- Timely Replacement

- Replace worn-out fittings to maintain system integrity.

Conclusion

Selecting the right PPR brass fitting involves understanding your project’s requirements, ensuring material quality, and consulting professionals when necessary. By following these guidelines, you can create a reliable and efficient plumbing or industrial system that stands the test of time.

FAQs

- What are the main uses of PPR brass fittings?

PPR brass fittings are commonly used in plumbing, heating, and industrial systems requiring durable and high-performing components. - How can I verify the quality of a PPR brass fitting?

Check for manufacturer certifications, inspect for defects, and ensure the brass used meets industry standards. - Are PPR brass fittings suitable for high-pressure systems?

Yes, they are designed to handle high-pressure applications effectively. - What are the common mistakes to avoid when choosing these fittings?

Avoid mismatched sizes, low-quality materials, and overlooking installation needs. - Why should I consult a professional when selecting PPR brass fittings?

Professionals help ensure compatibility, compliance with codes, and optimal system performance.