In recent years, the plumbing industry has increasingly focused on the safety and health implications of materials used in water systems. A significant development in this area is the incorporation of low-lead requirements into this standards. This change aims to reduce lead exposure in drinking water, ensuring safer plumbing solutions for homes and businesses.

Understanding Low-Lead Requirements

Low-lead regulations specify the maximum amount of lead that can be present in plumbing materials. The goal is to minimize the risk of lead leaching into drinking water, which can have serious health consequences, particularly for children and pregnant women. The U.S. Environmental Protection Agency (EPA) and various state regulations have tightened these requirements, prompting manufacturers to adapt their products accordingly.

Importance of Low-Lead PEX Fittings

- Health and Safety: Lead exposure is linked to various health issues, including developmental delays in children and cardiovascular problems in adults. By ensuring that PEX fittings meet low-lead standards, manufacturers contribute to safer drinking water supplies.

- Regulatory Compliance: Many states and municipalities have implemented stringent lead regulations. By adhering to these standards, manufacturers can ensure their products are compliant, facilitating easier acceptance in construction and renovation projects.

- Consumer Trust: As awareness of lead contamination grows, consumers are more likely to choose products that explicitly state their compliance with low-lead standards. This transparency helps build trust between manufacturers and consumers.

The Impact on PEX Fittings

Enhanced Manufacturing Processes

Manufacturers are now required to refine their processes to produce low-lead PEX fittings. This may involve sourcing alternative materials or employing new manufacturing techniques that reduce lead content. Companies that embrace these changes not only comply with regulations but also lead the way in innovation.

Testing and Certification

To ensure compliance with low-lead requirements, PEX fittings must undergo rigorous testing and certification processes. This includes verification from accredited testing laboratories that assess lead content in the materials used. Certifications from recognized organizations provide assurance that the products meet safety standards.

Industry Standards Update

The recent updates to industry standards now explicitly reference low-lead requirements, aligning with national and international regulations. This ensures that all PEX fittings produced are consistently safe for use in plumbing systems, further solidifying the role of PEX as a preferred material in the industry.

Benefits of Using Low-Lead PEX Fittings

- Reduced Risk of Contamination: Low-lead PEX fittings significantly minimize the risk of lead leaching into drinking water, promoting public health and safety.

- Long-Term Cost Savings: Investing in compliant materials can save money in the long run by preventing costly health-related issues and ensuring compliance with local regulations.

- Environmental Responsibility: By using low-lead materials, manufacturers contribute to environmental sustainability, reducing the overall lead content in plumbing systems.

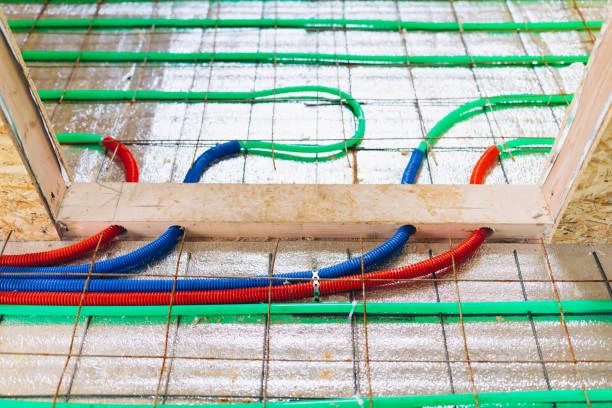

- Versatility and Durability: Low-lead PEX fittings maintain the same benefits as traditional PEX, including flexibility, resistance to corrosion, and ease of installation, making them an ideal choice for various plumbing applications.

Challenges and Solutions in Implementing Low-Lead Standards

While the benefits of low-lead PEX fittings are clear, implementing these standards has presented some challenges for manufacturers and installers. Here are some of the key issues and potential solutions:

- Cost Increases: The transition to low-lead materials and processes can result in higher production costs. Manufacturers may need to invest in new equipment, training, and testing capabilities to comply with the new standards. However, these costs can be offset by increased demand for low-lead products and potential cost savings from reduced liability and regulatory penalties.

- Supply Chain Disruptions: Finding suppliers of low-lead materials can be challenging, particularly in regions where the availability of these materials is limited. Manufacturers may need to expand their supplier base or work closely with existing suppliers to ensure a reliable supply of low-lead materials.

- Installer Training: Installers may require additional training to understand the differences between traditional and low-lead PEX fittings. Manufacturers and industry organizations can play a role in providing this training to ensure that installers are equipped to work with low-lead products safely and effectively.

The Future of PEX Fitting Standards

As the plumbing industry continues to evolve, so will the standards governing PEX fittings. Here are some trends and developments that are likely to shape the future of PEX fitting standards:

- Increased Focus on Sustainability: In addition to low-lead requirements, manufacturers are likely to face increasing pressure to adopt more sustainable practices. This may include the use of recycled materials, reduced energy consumption during manufacturing, and improved product lifecycles.

- Advancements in Material Science: Researchers are continually developing new materials and technologies that offer improved performance and environmental benefits. These advancements may lead to the development of even better PEX fittings that meet or exceed current standards.

- Global Harmonization of Standards: As the use of PEX fittings expands globally, there is a growing need for harmonization of standards across different regions. This will help to ensure consistency in quality and performance, facilitate trade, and promote the adoption of best practices worldwide.

Conclusion

The incorporation of low-lead requirements into it standards marks a significant step forward in ensuring the safety and quality of plumbing materials. As awareness of lead contamination continues to rise, the demand for compliant products will likely grow.

FAQs

- What are low-lead requirements?

- Low-lead requirements specify the maximum amount of lead allowed in plumbing materials to minimize health risks.

- Why are low-lead PEX fittings important?

- They help reduce the risk of lead contamination in drinking water, promoting safer water supplies.

- How can I ensure my PEX fittings meet low-lead standards?

- Look for certifications from recognized testing organizations that confirm compliance with low-lead regulations.

- Are low-lead PEX fittings more expensive?

- While they may be slightly more expensive than standard fittings, the long-term health benefits and regulatory compliance make them a worthwhile investment.

- Can I use low-lead PEX fittings in any plumbing application?

- Yes, low-lead PEX fittings are suitable for both hot and cold water applications in residential and commercial plumbing systems.