Plastic pipes fitting are essential components in various plumbing, construction, and industrial applications. They serve as connectors, adapters, and seals in a wide range of systems, ensuring that liquids and gases flow smoothly. Understanding the materials used in plastic pipes fitting can help you choose the right fittings for your specific needs, ensuring durability, safety, and efficiency.

Overview of Plastic Pipe Fittings

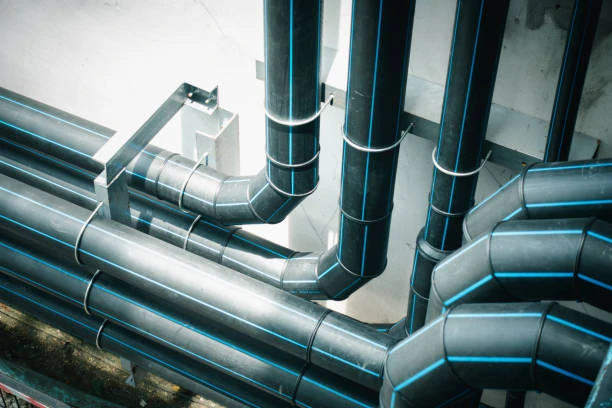

Plastic pipes fitting come in various shapes and sizes, designed to connect pipes, manage flow direction, and adapt to different pipe sizes. Common types include elbows, tees, couplings, and caps. These fittings are lightweight, resistant to corrosion, and easy to install, making them popular in residential, commercial, and industrial settings.

Common Materials Used in Plastic Pipe Fittings

Several materials are commonly used in the production of plastic pipe fitting. Each material offers unique properties that make it suitable for specific applications.

1. Polyvinyl Chloride (PVC)

PVC stands as one of the most widely used materials for plastics pipe fitting. It offers excellent chemical resistance, durability, and cost-effectiveness. Many plumbers commonly use PVC fittings in plumbing, drainage, and irrigation systems.

- Advantages of PVC:

- Lightweight and easy to handle

- Resistant to corrosion and chemicals

- Cost-effective compared to other materials

- Applications:

- Residential plumbing

- Drainage systems

- Irrigation systems

2. Chlorinated Polyvinyl Chloride (CPVC)

CPVC is a variant of PVC that has been treated with chlorine. This process enhances its temperature resistance, making it suitable for hot water applications. CPVC fittings are often used in residential and commercial plumbing systems.

- Advantages of CPVC:

- Higher temperature resistance than standard PVC

- Good chemical resistance

- Suitable for hot water applications

- Applications:

- Hot water plumbing

- Industrial applications involving corrosive chemicals

3. Polypropylene (PP)

Polypropylene is another popular material for plastic pipe fitting, particularly in food processing, chemical processing, and pharmaceutical applications. Its non-toxic properties and resistance to high temperatures make it an ideal choice for these industries.

- Advantages of Polypropylene:

- Non-toxic and safe for food applications

- Excellent chemical resistance

- High temperature tolerance

- Applications:

- Food and beverage processing

- Chemical manufacturing

- Pharmaceutical production

4. High-Density Polyethylene (HDPE)

HDPE is known for its strength and durability. It is resistant to impact, chemicals, and UV rays, making it suitable for outdoor applications. HDPE fittings are often used in water supply, gas distribution, and sewage systems.

- Advantages of HDPE:

- High strength-to-density ratio

- Excellent impact resistance

- UV resistant for outdoor applications

- Applications:

- Water supply systems

- Gas distribution

- Sewage and drainage systems

5. Acrylonitrile Butadiene Styrene (ABS)

ABS is a thermoplastic known for its toughness and impact resistance. Plumbers often use ABS fittings in drainage systems because they are easy to install and suitable for both residential and commercial applications.

- Advantages of ABS:

- High impact resistance

- Lightweight and easy to install

- Good chemical resistance

- Applications:

- Residential plumbing

- Drainage systems

- Ventilation systems

Choosing the Right Material for Your Application

When selecting plastic pipe fitting, consider the following factors:

1. Chemical Compatibility

Different materials have varying degrees of chemical resistance. Ensure that the fitting material is compatible with the substances it will transport.

2. Temperature Resistance

Consider the temperature of the fluids or gases passing through the pipes. Choose a fitting material that can withstand the operational temperature.

3. Application Environment

Evaluate the environment where the fittings will be installed. For outdoor applications, UV resistance and durability against weather conditions are important.

4. Regulatory Compliance

In industries like food processing and pharmaceuticals, ensure that the fittings meet relevant health and safety regulations.

Maintenance and Care for Plastic Pipe Fittings

Proper maintenance can extend the life of plastic pipe fitting. Here are some tips:

- Regular Inspections: Check for leaks, cracks, or signs of wear regularly.

- Cleaning: Use non-corrosive cleaners to maintain the fittings’ integrity.

- Avoid Over-tightening: When installing fittings, avoid over-tightening, which can lead to damage.

Conclusion

Understanding the materials used in plastic pipe fittings is crucial for selecting the right components for your specific needs. Whether you choose PVC, CPVC, polypropylene, HDPE, or ABS, each material offers distinct advantages and suits different applications. By considering factors such as chemical compatibility, temperature resistance, and environmental conditions, you can ensure optimal performance and durability in your piping systems.

FAQs

- What are plastic pipe fitting made from?

Plastic pipe fittings are commonly made from materials like PVC, CPVC, polypropylene, HDPE, and ABS. - Can plastic pipe fitting be used for hot water applications?

Yes, CPVC and certain types of polypropylene fittings are suitable for hot water applications. - How do I choose the right material for my project?

Consider factors like chemical compatibility, temperature resistance, and the specific environment where the fittings will be installed. - Are plastic pipe fitting safe for food applications?

Yes, materials like polypropylene are non-toxic and safe for food processing. - What maintenance do plastic pipe fitting require?

Regular inspections for leaks and cleaning with non-corrosive cleaners can help maintain the integrity of plastic pipe fittings.