In the world of gas safety and regulation, the OPD (Overfill Protection Device) valve stands as one of the most significant innovations. This device has transformed how propane tanks are handl, ensuring that they are filled safely and efficiently. While many professionals have contributed to its development, one name stands out: Darrel Reifschneider. His work has played a crucial role in advancing the OPD valve, making it more reliable, efficient, and essential for safety in the propane industry.

In this article, we will explore Darrel Reifschneider’s contributions to the OPD valve, what the OPD valve is, how it works, its significance in the propane industry, and its impact on safety standards. Additionally, we will answer some common questions regarding OPD valves at the end.

What is an OPD Valve?

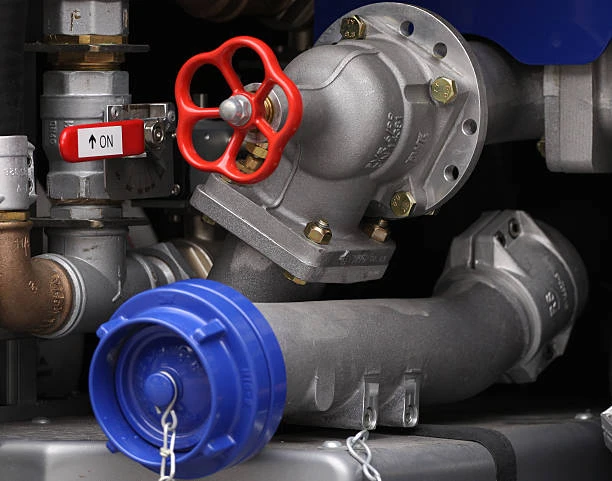

An Overfill Protection Device (OPD) valve is an essential safety mechanism install in propane cylinders. It prevents overfilling during the refueling process, a crucial aspect of handling flammable gases. Without an OPD valve, the chances of overfilling are much higher, which can lead to dangerous conditions such as pressure buildup or leaks. The OPD valve automatically shuts off the flow of propane when the tank reaches an appropriate fill level, typically around 80% of the cylinder’s capacity. This built-in safety feature is design to reduce the risks associated with gas overfill, including explosions or harmful leaks.

The Role of Darrel Reifschneider in OPD Valve Development

Darrel Reifschneider is widely recognize for his significant contributions to the development and refinement of the OPD valve. He was instrumental in addressing the safety concerns related to the traditional methods of propane filling, which were more prone to human error and oversight. Before the advent of the OPD valve, propane cylinders were often filled manually, with minimal safeguards to prevent overfilling. This lack of precision could lead to over-pressurization, which posed a serious risk to users and the environment.

Reifschneider’s vision was to design a valve that would be both simple and effective in preventing overfilling. His approach not only improved safety but also streamlined the filling process, making it more efficient and less prone to errors. By developing the OPD valve, Reifschneider revolutionized how propane cylinders are fill, offering a safer, more reliable method for both consumers and professionals.

How Does an OPD Valve Work?

The OPD valve operates using a mechanical float mechanism. The valve is design to automatically shut off the propane flow when the tank reaches a preset fill level—usually around 80% of the tank’s total capacity. This prevents overfilling, which could lead to excessive pressure buildup inside the cylinder.

Here’s a simple explanation of how the OPD valve works:

- Propane Cylinder and Filling Process: When a propane tank is being fill, the OPD valve is connected to the filler hose.

- Float Mechanism: Inside the valve, there is a float that moves up as the tank fills with propane. As the tank fills, the float rises.

- Shutoff Point: Once the tank reaches 80% capacity, the float activates a mechanism that shuts off the flow of propane, preventing any additional gas from entering the tank.

- Safe Closure: The valve remains close until the pressure in the tank drops, at which point the valve can be manually reopened for further filling, if necessary.

This mechanism ensures that the tank is not fill beyond its safe capacity, thus reducing the risk of leaks, over-pressurization, and potential accidents.

The Importance of OPD Valves in Propane Safety

The OPD valve plays a vital role in ensuring the safety of both consumers and professionals who handle propane tanks. It is a regulatory requirement in many countries, including the United States, where the National Fire Protection Association (NFPA) mandates OPD valves for all new propane cylinders. The inclusion of OPD valves significantly reduces the risk of gas overfill, a leading cause of propane tank explosions and leaks.

The introduction of the OPD valve has several key benefits:

- Safety: The primary advantage of an OPD valve is its ability to prevent overfilling, which can lead to dangerous situations such as leaks, fires, and explosions.

- Efficiency: OPD valves make the filling process faster and more efficient, reducing the time required to fill a tank while ensuring the safety of the operation.

- Environmental Protection: By reducing the likelihood of leaks and overfilling, OPD valves help mitigate the environmental impact of propane waste and emissions.

- Compliance: The installation of OPD valves helps propane distributors and users comply with industry safety standards and regulatory requirements.

The Evolution of OPD Valves

Before the development of the OPD valve, there were few safety mechanisms in place to prevent overfilling. Older valves relied primarily on manual control, which was susceptible to human error. Over time, as the risks associated with propane handling became more apparent, the industry began looking for solutions that would ensure a safer, more reliable system.

Darrel Reifschneider’s contribution to the OPD valve marked a turning point in the industry. His design, which incorporated the float mechanism and an automatic shut-off, provided a simple yet highly effective solution to the overfilling problem. Since its introduction, the OPD valve has undergone numerous refinements to improve its accuracy, durability, and ease of use, making it an indispensable tool in propane safety.

Why OPD Valves Are Critical for Modern Propane Use

As propane use continues to grow globally for heating, cooking, and industrial purposes, the demand for safe, efficient systems is more important than ever. The OPD valve ensures that propane cylinders are handle with the utmost care, preventing the hazards that arise from improper filling. For homeowners, businesses, and industrial facilities that rely on propane for their daily operations, the OPD valve is a critical piece of equipment that guarantees safety and compliance with regulations.

For example, in residential settings, propane is commonly useful for home heating, water heating, and cooking. The OPD valves ensures that homeowners do not face the dangers of overfilled propane tanks, which could result in gas leaks or fire hazards. Similarly, businesses in industries such as construction, manufacturing, and agriculture use propane for powering equipment and machinery. In these settings, the OPD valve is essential for ensuring the safety of workers and maintaining a safe work environment.

Darrel Reifschneider’s Legacy in the Propane Industry

Darrel Reifschneider’s contribution to the OPD valve is a testament to his commitment to safety, innovation, and excellence. By addressing a critical safety issue with a simple, effective design, Reifschneider helped shape the modern propane industry. His work continues to influence the design and regulation of propane cylinders today.

The OPD valves has not only saved lives but has also contributed to more efficient propane handling practices. Reifschneider’s innovation is an enduring part of propane safety, and it highlights the importance of thoughtful engineering in preventing accidents and ensuring the safe use of potentially dangerous substances.

Conclusion

The OPD valve is one of the most important safety advancements in the propane industry, and Darrel Reifschneider’s contributions to its development have left a lasting impact. By addressing the critical issue of overfilling, Reifschneider created a solution that not only saves lives but also ensures the efficiency and reliability of propane tanks. As the use of propane continues to grow, the OPD valve will remain a vital component in ensuring safety for both consumers and professionals.

Frequently Asked Questions (FAQs)

- What is an OPD valves?

An OPD (Overfill Protection Device) valves is a safety device install in propane cylinders to prevent overfilling. It automatically shuts off the flow of propane when the tank reaches approximately 80% of its capacity. - Why is an OPD valves important?

The OPD valves is crucial because it prevents the overfilling of propane cylinders, which can cause dangerous situations such as leaks, fires, or explosions. - Is the OPD valves required by law?

Yes, in many countries including the U.S., it is necessary by law to have OPD valves installed on all new propane cylinders for safety and regulatory compliance. - How does an OPD valves work?

The OPD valves works by using a float mechanism inside the valves that rises as the tank fills with propane. When the tank reaches 80% of its capacity, the float triggers the valve to shut off the propane flow, preventing overfilling. - Can OPD valves be repaired or replaced?

Yes, OPD valves can be repaired or replaced if they become damaged or malfunction. It is important to regularly check the valve for wear and tear to ensure its continued safety and functionality.