The Florence Water Treatment Plant recently undergoes valve replacement as part of a major initiative to improve water supply reliability and efficiency. Valves are crucial components in water treatment infrastructure, controlling flow, pressure, and distribution across the system. Upgrading these components ensures uninterrupted service and optimal performance, especially in regions with increasing demand for clean water.

This article explores the significance of the undergoes valve replacement project, its impact on the plant’s operations, and the benefits for the community it serves.

Overview of the Florence Water Treatment Plant

The Florence Water Treatment Plant is a critical part of the region’s infrastructure, supplying potable water to thousands of residents and businesses. Built decades ago, the facility has undergone numerous upgrades to keep pace with modern demands.

Challenges Before the Upgrade:

- Aging Valves: Many valves were outdated, prone to leaks, and inefficient.

- Frequent Maintenance: Old components required constant repairs, increasing downtime and operational costs.

- Rising Demand: Population growth strained the plant’s ability to maintain consistent supply.

The decision to replace key valves was a proactive measure to address these challenges and future-proof the plant’s operations.

Why Valve Replacement Was Necessary

Valves play a vital role in water treatment processes, from regulating flow to ensuring safety during emergencies. At the Florence facility, the aging valves posed several risks:

1. Leaking and Water Loss

Old valves often leaked, wasting significant amounts of treated water and increasing costs.

2. Reduced Efficiency

Worn-out valves impeded precise flow control, reducing overall plant efficiency.

3. Operational Delays

Frequent malfunctions led to disruptions in water distribution, affecting the community.

Replacing these outdated components with modern, high-performance valves became essential to meet service expectations and regulatory standards.

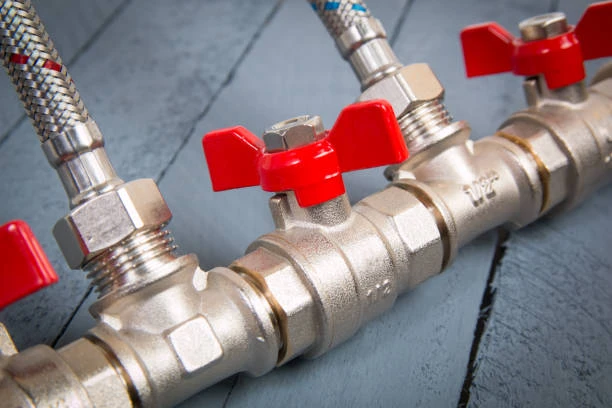

Key Features of the New Valves

The upgraded valves offer state-of-the-art technology tailored to the needs of modern water treatment plants.

Features:

- Advanced Materials

Constructed with corrosion-resistant materials, the valves ensure long-term durability in wet environments. - Smart Technology

Equipped with sensors and IoT integration, the valves enable real-time monitoring of flow, pressure, and system health. - Energy Efficiency

Modern designs minimize energy consumption, reducing operational costs and environmental impact. - Emergency Shutoff Capabilities

The new valves include rapid shutoff mechanisms to prevent water loss during system failures. - Improved Flow Control

Enhanced precision ensures water flows smoothly and consistently, even under high-demand conditions.

Installation Process and Challenges

The valve replacement project was a complex operation, requiring meticulous planning and execution to minimize disruption.

Steps Involved:

- System Assessment

Engineers conducted a thorough review to identify critical valves needing replacement. - Shutdown and Preparation

Sections of the plant were temporarily shut down to allow for safe removal of old valves. - Valve Installation

New valves were installed using advanced techniques to ensure proper alignment and sealing. - Testing and Calibration

Extensive testing confirmed the valves’ performance and integration with the plant’s control systems. - System Restart

The upgraded sections were brought back online, with continuous monitoring for any issues.

Challenges Encountered:

- Tight Deadlines: Ensuring minimal disruption to water supply during the upgrade.

- Complex Network: Navigating the plant’s intricate network of pipes and valves.

- Environmental Considerations: Preventing contamination during the replacement process.

Benefits of the Valve Replacement Project

The completion of the valve replacement project has yielded numerous benefits for the Florence Water Treatment Plant and the community.

1. Increased Reliability

The new valves significantly reduce the risk of failures, ensuring consistent water supply to residents and businesses.

2. Enhanced Efficiency

Improved flow control and reduced water loss optimize the plant’s performance, lowering operational costs.

3. Environmental Sustainability

The energy-efficient design of the valves aligns with the plant’s commitment to sustainability by reducing its carbon footprint.

4. Cost Savings

Fewer maintenance needs and lower energy consumption translate into long-term cost savings for the utility provider.

5. Better Service to the Community

With upgraded infrastructure, the plant is better equipped to meet the growing demand for clean water, even during peak periods.

Broader Implications for Water Treatment Infrastructure

The Florence Water Treatment Plant’s successful valve replacement highlights the importance of regular infrastructure upgrades. Across the globe, aging water systems face similar challenges, making investments in modern technology crucial for sustainable water management.

Key Takeaways:

- Proactive Maintenance: Addressing issues before they escalate prevents costly failures and service disruptions.

- Smart Technology Integration: Advanced valves with monitoring capabilities enhance efficiency and decision-making.

- Community Impact: Modernized infrastructure improves service quality, fostering public trust and satisfaction.

Conclusion

The Florence Water Treatment Plant’s decision to undergo valve replacement reflects its commitment to operational excellence and community service. By upgrading to modern, high-performance valves, the plant has positioned itself to meet current and future demands effectively.

This project underscores the vital role of infrastructure investments in ensuring reliable and sustainable access to clean water. As other facilities face similar challenges, Florence’s example provides a roadmap for successful modernization.

FAQs About Valve Replacement in Water Treatment Plants

1. Why are valve replacements important in water treatment plants?

The undergoes valve replacements ensure efficient flow control, reduce water loss, and improve the overall reliability of the system.

2. What challenges arise during valve replacement projects?

Common challenges include minimizing disruptions to water supply, navigating complex pipe networks, and ensuring environmental safety during the process.

3. How do smart valves benefit water treatment facilities?

Smart undergoes valve offer real-time monitoring, enhanced precision, and reduced maintenance needs, improving operational efficiency.

4. What materials are used in modern valves?

Modern undergoes valve often use corrosion-resistant materials like stainless steel or specialized alloys to ensure durability.

5. How often should valves in a water treatment plant be replaced?

The lifespan of valves depends on their material, usage, and maintenance. Regular inspections help determine the right time for replacement.