In the realm of food processing and other industries that utilize spray drying technology, efficient and reliable equipment is paramount. GEA, a global leader in process technology, has recently introduced its innovative CONTA Dual Block Valve technology specifically designed for spray dryers. This new development aims to enhance operational efficiency, product quality, and safety standards in spray drying applications. In this article, we will explore the features and benefits of the CONTA Dual Block Valve, its role in spray dryer systems, and its implications for the industry.

Understanding Spray Drying Technology

What Is Spray Drying?

Spray drying is a widely used method for transforming liquid products into powder form. This technique involves atomizing a liquid feed into fine droplets, which are then dried rapidly by hot air in a drying chamber. The resulting powder can be used in various applications, including food, pharmaceuticals, and chemicals.

The Importance of Valves in Spray Dryers

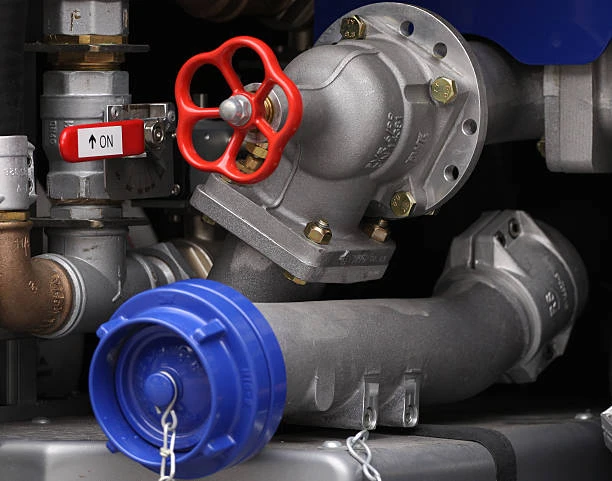

Valves play a crucial role in the efficient operation of spray dryers. They control the flow of materials, regulate pressure, and ensure proper sealing to prevent contamination. A malfunctioning valve can lead to significant downtime, product loss, and safety hazards.

Introducing the CONTA Dual Block Valve Technology

Key Features of the CONTA Dual Block Valve

GEA’s CONTA Dual Block Valve technology is designed to address the challenges faced in traditional spray drying systems. Here are its key features:

- Dual Blocking Mechanism: The CONTA valve incorporates a dual blocking design, allowing for effective sealing and isolation of product flow. This minimizes the risk of contamination and ensures product integrity.

- Enhanced Safety: With its innovative design, the CONTA valve enhances safety by preventing the backflow of materials, reducing the likelihood of leaks and spills.

- Compact Design: The valve’s compact design allows for easy integration into existing spray dryer systems, saving valuable space and simplifying installation.

- Robust Materials: Constructed from high-quality materials, the CONTA valve is built to withstand the demanding conditions of spray drying processes, ensuring durability and longevity.

- User-Friendly Operation: The valve is designed for easy operation and maintenance, reducing the time and effort required for routine checks and repairs.

Benefits of the CONTA Dual Block Valve Technology

1. Improved Product Quality

The dual blocking mechanism of the CONTA valve ensures a secure seal, preventing contamination from external sources. This is critical in industries such as food processing, where product purity is paramount. By maintaining the quality of the end product, manufacturers can enhance their reputation and customer satisfaction.

2. Increased Operational Efficiency

By preventing leaks and maintaining consistent flow rates, the CONTA valve contributes to smoother operations within spray drying systems. This results in reduced downtime and improved throughput, ultimately leading to higher productivity.

3. Enhanced Safety Standards

The CONTA valve’s design mitigates risks associated with leaks and spills, promoting a safer working environment for operators. This is particularly important in industries handling hazardous materials, where safety regulations are stringent.

4. Cost-Effectiveness

Investing in advanced valve technology can lead to long-term cost savings. By reducing the risk of product loss and minimizing maintenance requirements, the CONTA valve can enhance the overall return on investment for spray drying operations.

5. Environmental Benefits

By improving efficiency and reducing waste, the CONTA Dual Block Valve technology aligns with sustainability goals. Companies can achieve better resource utilization while minimizing their environmental impact.

The Role of Valves in Process Optimization

Integrating the CONTA Valve into Spray Drying Systems

To fully leverage the benefits of the CONTA Dual Block Valve, manufacturers must ensure its proper integration into their existing spray drying systems. This includes:

- System Assessment: Evaluating the current spray drying setup to identify suitable locations for valve installation.

- Training and Support: Providing operators with the necessary training to understand the valve’s functionality and maintenance requirements.

- Continuous Monitoring: Implementing monitoring systems to track the performance of the valve and detect any potential issues early.

Best Practices for Valve Maintenance

Regular maintenance is essential to ensure the longevity and reliability of the CONTA valve. Key maintenance practices include:

- Routine Inspections: Conducting regular inspections to check for wear and tear, leaks, and other signs of potential failure.

- Cleaning: Keeping the valve clean and free from contaminants to ensure smooth operation.

- Timely Repairs: Addressing any identified issues promptly to prevent further complications and downtime.

Market Implications of the CONTA Dual Block Valve Technology

Competitive Advantage

The introduction of GEA’s CONTA Dual Block Valve technology provides manufacturers with a competitive edge in the spray drying market. As industries increasingly prioritize efficiency, safety, and product quality, the adoption of advanced valve technology will become a differentiating factor.

Industry Trends

The demand for high-quality, safe, and efficient processing solutions is driving innovations in valve technology. The CONTA valve aligns with broader industry trends focusing on automation, sustainability, and cost-effectiveness.

Conclusion

GEA’s CONTA Dual Block Valve technology represents a significant advancement in the field of spray drying. By enhancing safety, improving product quality, and increasing operational efficiency, this innovative valve solution addresses critical challenges faced by manufacturers. As the industry continues to evolve, the integration of advanced technologies like the CONTA valve will be crucial for achieving sustainable and competitive operations.

FAQs

1. What is a dual block valve?

A dual block valve is a valve designed with a dual sealing mechanism that provides effective isolation and prevents contamination in fluid systems.

2. How does the CONTA Dual Block Valve improve safety?

The CONTA valve enhances safety by preventing leaks and backflow of materials, reducing the risk of spills and contamination.

3. What industries benefit from using the CONTA Dual Block Valve?

Industries such as food processing, pharmaceuticals, and chemicals benefit from the reliability and efficiency of the CONTA valve in spray drying applications.

4. What maintenance practices are recommended for the CONTA valve?

Routine inspections, cleaning, and timely repairs are essential maintenance practices to ensure the valve operates effectively and lasts longer.

5. How does the CONTA valve contribute to sustainability?

By improving efficiency and reducing waste, the CONTA Dual Block Valve technology supports sustainability goals, allowing companies to utilize resources more effectively.