Introduction

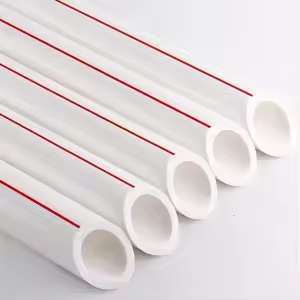

Selecting the correct size of PPR (Polypropylene Random Copolymer) pipe fittings DIN 8077/8078 is crucial for ensuring the efficiency and reliability of any plumbing system. Using properly sized fittings ensures optimal water flow, prevents leaks, and extends the system’s lifespan. This guide will help you understand the key factors involved in choosing the right size PPR pipe fittings for your specific needs.

Key Factors to Consider When Choosing PPR Pipe Fittings

- Pipe Diameter

- The first step in selecting the right fittings is to match the fitting size with the diameter of the PPR pipe. PPR pipes come in various sizes, typically measured in millimeters (mm), such as 20mm, 25mm, 32mm, 40mm, and beyond. Always ensure that the fitting’s internal diameter matches the external diameter of the pipe.

- Common PPR pipe sizes: 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm.

- Type of Connection

- PPR fittings come in several types depending on how they connect to the pipe. Choose fittings that match your system’s connection requirements:

- Socket fusion fittings: Commonly used for joining PPR pipes. A fusion tool melt the pipe and fitting together leak-proof joint.

- Threaded fittings: These fittings PPR pipes to. The correct thread size is essential.

- Electrofusion fittings: These fittings use electric currents to create strong, permanent joints, often used in more demanding applications.

System Pressure Rating

- PPR fittings, like pipes, are available in various pressure ratings, typically indicated as PN (pressure nominal), such as PN10, PN16, PN20, or PN25. The rating indicates the pressure (in bars) the fittings can handle. Make sure to choose fittings that match the pressure requirements of your system. Higher pressure ratings (PN20 or PN25) typically water or industrial applications, while lower ratings (PN10 or PN16) are suitable for cold water systems.

- Type of Fitting

- There are many types of PPR fittings designed for different purposes. It’s important to choose the correct fitting type for your system:

- Elbows: Used to change the direction of the pipe (e.g., 45° or 90°).

- Tees: Allow for branching in the piping system.

- Couplings: Join two straight pipes together.

- Reducers: Connect pipes of different diameters.

- Caps: Close the end of a pipe.

- Adapters: Used to transition from PPR to other materials, like metal.

- Flow Requirements

- The size of the fitting should be chosen based on the required flow rate. Pipes with smaller diameters have higher resistance to flow, while larger pipes can handle higher flow rates. It’s important to consider the overall size of the piping system and match the fittings accordingly to maintain proper water flow without causing pressure drops.

- Application Type

- Hot water systems: For systems involving hot water, it’s essential to choose PPR fittings that can handle high temperatures and pressures. Ensure you select fittings with a higher pressure rating, such as PN20 or PN25.

- Cold water systems: In cold water supply lines, fittings with a lower pressure rating, such as PN10 or PN16, may suffice.

- Industrial applications: For chemical or industrial applications, special chemical-resistant fittings may be needed. Ensure that the selected PPR fittings are suitable for the fluids being transported.

Steps for Choosing the Right PPR Pipe Fittings

- Determine the Pipe Size: Measure the external diameter of the PPR pipe, and choose a fitting that corresponds to this size.

- Select the Pressure Rating: Identify the pressure requirements of your system (PN10, PN16, PN20, etc.) and choose fittings that meet or exceed this rating.

- Match the Fitting Type: Depending on the function (e.g., connecting two pipes, changing direction, branching, or reducing size), choose the appropriate fitting type, such as elbow, tee, or reducer.

- Ensure Compatibility: If connecting PPR pipes to other materials (e.g., metal), make sure to choose the right adapters or transition fittings, such as threaded or flange fittings.

- Consider the Application: Whether for residential plumbing, industrial piping, or irrigation, ensure the fittings meet the temperature, chemical, and flow rate requirements of the system.

Conclusion

Choosing the right size PPR pipe fittings involves understanding your system’s pipe diameter, pressure rating, and connection type. Proper selection ensures efficient water flow, system reliability, and longevity. By carefully evaluating your project’s specific requirements, you can ensure a leak-proof and long-lasting plumbing solution with the appropriate PPR fittings.