Water quality and efficiency are crucial considerations for any municipality. For cities like Hamilton, managing the water supply in both residential and industrial areas is a complex, ongoing task that demands the latest technology to ensure continuous service and reduce long-term costs. One such innovation that has proven to be highly effective in ensuring a steady water flow and saving the city significant amounts of money is the use of anti-stagnation valves.

In this article, we will explore the role of anti-stagnation valves in maintaining water systems, how they work, and how Hamilton has benefited from their installation. By examining real-world examples, we can understand how these valves help reduce water stagnation, conserve resources, and provide long-term savings.

What Are Anti-Stagnation Valves?

Anti-stagnation valves are specialized devices designed to prevent water from stagnating within pipelines, particularly in systems where water is not constantly in motion. In water distribution networks, stagnant water can lead to several problems, including bacterial growth, unpleasant tastes, and even system inefficiencies. Stagnant water can occur in dead-end pipes, long distribution lines, or areas where there is low demand for water, causing the water to sit idle for extended periods.

How Anti-Stagnation Valves Work

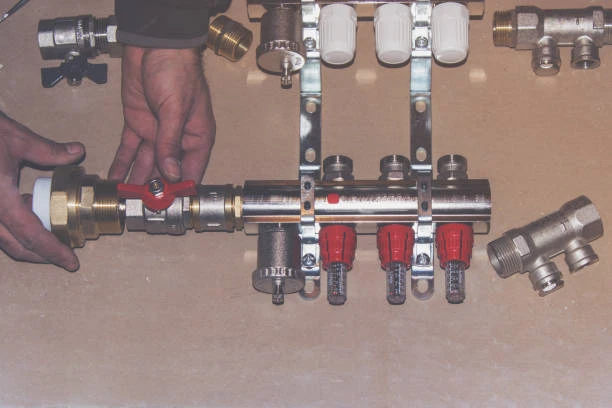

These valves are engineered to open automatically when water flow falls below a certain threshold. By doing so, they ensure that water circulates consistently through the system, preventing stagnation. The valves help to keep the water moving, which not only maintains water quality but also improves the overall efficiency of the distribution network.

The valves can be installed at various points within the water system, including at the ends of long pipelines or in areas prone to low flow. The design typically includes a flow sensor that detects when the flow of water is too slow, triggering the valve to open and release water into the pipeline to keep it moving. The result is a reduction in stagnation, which helps mitigate the risk of contaminants and inefficiencies in the water supply system.

The Problems Caused by Stagnant Water

Stagnant water in municipal water systems can lead to a variety of issues. These problems not only affect the quality of the water but can also strain a city’s resources, making anti-stagnation measures even more important. Here are some of the key problems associated with stagnant water in water distribution systems:

1. Bacterial Growth

Water that sits idle in pipes provides a perfect environment for bacteria to grow. Over time, this can result in the contamination of the water supply, leading to public health concerns. Bacteria such as Legionella can proliferate in stagnant water, and if the system is not properly disinfected, it could pose significant health risks to the community.

2. Unpleasant Tastes and Odors

Water that has been stagnant for a prolonged period often develops unpleasant tastes and odors. This is due to the natural breakdown of organic materials that occur when water sits still. Municipal water treatment plants can filter and disinfect water before it reaches residents, but if the water becomes stagnant in the distribution system, these contaminants can re-enter the system and degrade water quality.

3. Waste of Resources

Stagnation also wastes resources. In systems where water is allowed to sit for too long, utilities may need to flush the system to remove stale or contaminated water, which can result in the loss of significant volumes of clean water. Flushing can be costly in terms of both the water and energy required to perform the process, not to mention the added labor costs.

4. Lower System Efficiency

Water stagnation can reduce the overall efficiency of the water supply network. Low flow or stagnant water leads to increased energy use as pumps work harder to push water through the system. This not only increases operational costs but also contributes to the wear and tear of the system, leading to higher maintenance and replacement costs over time.

Hamilton’s Approach to Anti-Stagnation Valves

Hamilton, a city known for its industrial and residential areas, has faced its share of water management challenges. As a growing city, its water infrastructure must meet the demands of a diverse population while dealing with complex water distribution systems that span residential areas, commercial districts, and industrial zones. The installation of anti-stagnation valves has been a strategic move by Hamilton’s municipal water authorities to combat issues caused by stagnant water and to improve the overall efficiency of the water distribution network.

Case Study: How Anti-Stagnation Valves Saved Hamilton

Hamilton’s water authority began investing in anti-stagnation valves several years ago after noticing that certain areas of the city’s water distribution system experienced significant stagnation due to low demand. In these areas, water would sit idle for extended periods, leading to bacterial growth, unpleasant odors, and inefficiencies. By installing anti-stagnation valves, the city was able to address these issues while realizing long-term savings.

Improved Water Quality

With the valves in place, water is constantly circulating, preventing stagnation and ensuring that the water remains fresh and of high quality. The valves have helped to reduce incidents of bacterial growth and water contamination, which are crucial for maintaining public health. The continuous flow also eliminates the buildup of unpleasant tastes and odors, which had previously been a significant issue in some neighborhoods.

Reduced Flushing Costs

Previously, the city had to periodically flush sections of the distribution system to remove stale water. Flushing, while effective, was an expensive and resource-intensive process. With the introduction of anti-stagnation valves, Hamilton was able to significantly reduce the need for flushing, saving both water and energy. The valves keep the water moving, preventing stagnation before it becomes a problem.

Lower Energy Consumption

With reduced stagnation and a more consistent flow of water, the overall energy consumption of the water distribution system has decreased. Pumps no longer need to work as hard to push water through areas with low demand. This has led to a reduction in the city’s energy costs, making the water supply system more sustainable and efficient.

Extended Infrastructure Lifespan

By keeping the water moving and preventing stagnation, Hamilton has also been able to extend the lifespan of its water infrastructure. Reduced stagnation means less wear and tear on the system’s pipes and pumps, leading to lower maintenance costs and fewer repairs. Over time, this extends the useful life of the city’s water distribution infrastructure, which is a significant financial advantage for the municipality.

The Financial Benefits of Anti-Stagnation Valves

The financial benefits of anti-stagnation valves are clear, especially when considering the savings in terms of water quality, energy, and maintenance costs. Here are some of the key financial advantages:

- Reduced Water Wastage Anti-stagnation valves eliminate the need for frequent flushing of the water system. Flushing is a costly operation, involving the loss of both water and energy. By keeping the water circulating, Hamilton has reduced these unnecessary costs.

- Lower Energy Bills With improved flow dynamics, the water pumps require less energy to maintain optimal pressure throughout the system. This results in significant energy savings for the city, particularly in areas where low water flow was previously causing inefficiencies.

- Fewer System Failures By preventing stagnation and the associated issues of bacterial growth and corrosion, Hamilton has reduced the occurrence of system failures. This, in turn, reduces the financial burden of emergency repairs and unscheduled maintenance.

- Long-Term Savings on Infrastructure Anti-stagnation valves contribute to the longevity of the water system. By reducing the risk of pipe corrosion and maintaining a more consistent flow of water, the city’s infrastructure is better protected, which helps extend its life and delays the need for costly replacements.

Conclusion

Hamilton’s investment in anti-stagnation valves has proven to be a wise decision, bringing both environmental and financial benefits to the city. By preventing stagnant water, improving water quality, reducing operational costs, and extending the life of infrastructure, anti-stagnation valves are an essential part of Hamilton’s strategy for efficient and sustainable water management.

As other cities face similar challenges with their water systems, Hamilton’s success with anti-stagnation valves serves as a model for how innovative technology can save money, improve water quality, and contribute to the overall health of a community. By embracing such solutions, municipalities can continue to ensure that their water systems are reliable, safe, and cost-effective for years to come.

Frequently Asked Questions (FAQ)

1. What is an anti-stagnation valve?

An anti-stagnation valve is a device installed in water distribution systems to prevent water from stagnating in the pipes. The valve automatically opens when water flow is too low, ensuring continuous circulation and preventing issues like bacterial growth and water contamination.

2. How do anti-stagnation valves work?

Anti-stagnation valves work by sensing when water flow falls below a certain level. When this happens, the valve opens to allow water to flow through the system, keeping the water moving and preventing stagnation.

3. What are the benefits of anti-stagnation valves?

The benefits of anti-stagnation valves include improved water quality, reduced water wastage, lower energy consumption, and fewer system failures. These valves help to extend the life of infrastructure and reduce operational costs.

4. Why is stagnation a problem in water systems?

Stagnation in water systems can lead to bacterial growth, unpleasant tastes and odors, and wasted water. It can also reduce the overall efficiency of the water distribution system, leading to higher energy and maintenance costs.

5. How has Hamilton benefited from anti-stagnation valves?

Hamilton has benefited from anti-stagnation valves by improving water quality, reducing the need for flushing, lowering energy consumption, and extending the lifespan of its water infrastructure. These improvements have led to significant cost savings for the city.