The global Multi Tandem Valve market continues to evolve as industries demand efficient and versatile hydraulic solutions. These valves are integral to various sectors, from construction to agriculture, where precise hydraulic control is essential. In 2024, advancements in technology, increasing industrialization, and a focus on sustainability are driving this market forward.

This article delves into the market trends, key drivers, challenges, and future outlook for the Multi Tandem Valve industry, offering a comprehensive guide for stakeholders and industry professionals.

What is a Multi Tandem Valve?

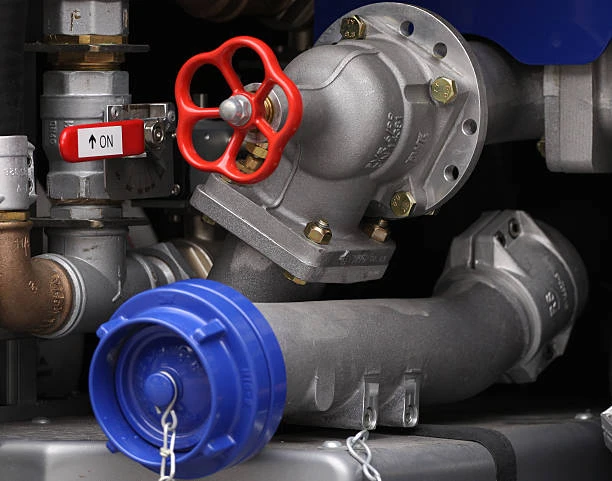

A Multi Tandem Valve is a hydraulic component that allows the operation of multiple flow paths simultaneously. Its design ensures seamless control and distribution of hydraulic energy, making it a critical part of complex machinery.

Key Characteristics:

- Multiple Flow Paths: Enables the operation of several hydraulic functions concurrently.

- Compact Size: Ideal for systems requiring space optimization.

- Robust Construction: Handles high pressure and extreme conditions.

- Customizability: Adapts to the unique needs of different industries.

Primary Uses:

- Heavy equipment in construction and agriculture.

- Industrial machinery in manufacturing plants.

- Specialized systems in the oil and gas sector.

Market Analysis

Market Size and Growth Projections

The Multi Tandem Valve market is poised to grow at a CAGR of approximately 7.5% between 2024 and 2030. This growth stems from the increasing adoption of automated machinery, rising infrastructure development, and innovations in hydraulic technologies.

Regional Overview

- North America: A mature market with consistent demand due to advanced manufacturing and construction industries.

- Europe: A hub for innovation, focusing on sustainable and efficient hydraulic solutions.

- Asia-Pacific: The fastest-growing market, driven by rapid industrialization and infrastructure expansion in countries like China and India.

- Middle East and Africa: Emerging markets with growing investments in construction and oil exploration projects.

Key Market Drivers

Industrial Automation

Automation is reshaping industries, necessitating hydraulic systems capable of delivering precision and efficiency. Multi Tandem Valves meet these demands by ensuring smooth operations in automated processes.

Infrastructure Development

Governments worldwide are investing heavily in infrastructure projects. This trend directly boosts demand for machinery equipped with high-performance Multi Tandem Valves.

Focus on Sustainability

Manufacturers are designing energy-efficient valves that align with global sustainability goals, further driving market growth.

Challenges Facing the Market

- High Costs: The initial investment for advanced Multi Tandem Valves can deter smaller businesses.

- Technical Complexity: Proper installation and maintenance require skilled personnel.

- Supply Chain Issues: Global supply chain disruptions impact the availability of raw materials and components.

Technological Advancements

Smart Hydraulic Systems

Integration of IoT and AI into hydraulic systems allows real-time monitoring, predictive maintenance, and improved efficiency.

Lightweight and Durable Materials

Innovative materials such as advanced alloys and composites extend the lifespan of Multi Tandem Valves while reducing system weight.

Customization for Specific Applications

Manufacturers offer tailor-made solutions to address unique industry requirements, such as valves designed for extreme environments in the oil and gas sector.

Industry Applications

Agriculture

Farm machinery, such as tractors and harvesters, use Multi Tandem Valves to control implements like plows and seeders.

Construction

Excavators, bulldozers, and cranes rely on these valves to manage multiple hydraulic functions simultaneously.

Manufacturing

Production lines and hydraulic presses benefit from the precision and reliability of Multi Tandem Valves.

Oil and Gas

Drilling rigs and exploration equipment depend on these valves for critical operations under high pressure.

Competitive Landscape

Leading companies in the Multi Tandem Valve market include:

- Bosch Rexroth AG: Known for innovative and high-performance hydraulic solutions.

- Parker Hannifin Corporation: A leader in motion and control technologies.

- Eaton Corporation: Renowned for its broad range of hydraulic components.

- Danfoss Group: Focused on sustainability and efficiency in hydraulic systems.

- Kawasaki Heavy Industries, Ltd.: Specializes in heavy-duty valves for industrial use.

Future Trends

Increased Adoption of Smart Valves

As industries embrace digital transformation, smart Multi Tandem Valves will see greater adoption due to their ability to optimize system performance and reduce downtime.

Growth in Emerging Markets

Countries in Asia-Pacific and Africa will play a crucial role in driving market expansion, supported by economic growth and infrastructure development.

Sustainability Initiatives

Manufacturers will continue innovating to create eco-friendly and energy-efficient solutions, aligning with global environmental goals.

Conclusion

The Multi Tandem Valve market in 2024 promises robust growth and innovation. With increasing industrialization, advancements in technology, and a focus on sustainability, the industry is set to flourish. Stakeholders can capitalize on these opportunities by staying informed about market trends and technological advancements.

FAQs

1. What is driving the growth of the Multi Tandem Valve market?

The demand for automation, infrastructure development, and sustainability-focused solutions are the primary growth drivers.

2. How do Multi Tandem Valves improve equipment efficiency?

They enable simultaneous control of multiple hydraulic functions, enhancing system performance and reducing energy consumption.

3. Which industries benefit most from Multi Tandem Valves?

Agriculture, construction, manufacturing, and oil and gas are the primary beneficiaries.

4. What are the latest innovations in Multi Tandem Valves?

Key innovations include IoT-enabled smart valves, lightweight materials, and customized designs for specific applications.

5. Are Multi Tandem Valves suitable for extreme environments?

Yes, many valves are designed to operate under high pressure and harsh conditions, making them ideal for demanding applications.