In the realm of industrial automation, precision and control are paramount. Festo, a global leader in automation technology, has recently unveiled the first high-precision proportional valve terminal, marking a significant advancement in pneumatic control systems. This innovation not only enhances the efficiency of industrial processes but also opens up a plethora of new applications across various sectors. In this article, we will explore the importance of high-precision proportional valves, their applications, and the transformative impact of Festo’s latest technology.

Understanding High-Precision Proportional Valves

What Are High-Precision Proportional Valves?

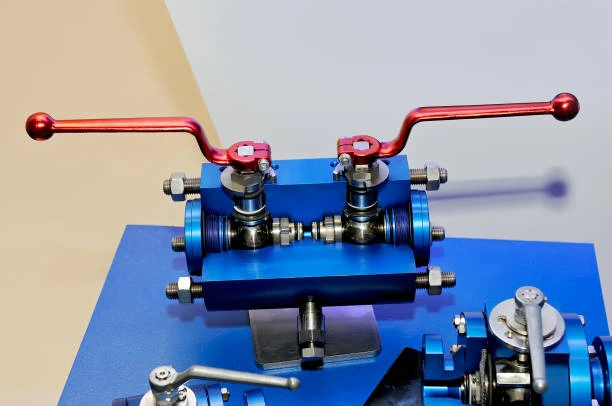

High-precision proportional valves are specialized devices used to control the flow and pressure of fluids with remarkable accuracy. Unlike traditional on/off valves, proportional valves adjust the flow in proportion to an input signal, allowing for finer control of the system. This capability is crucial in applications where precision is essential.

How Do They Work?

High-precision proportional valves operate by modulating the valve opening based on an electrical signal. The valve’s position is continuously adjusted to maintain the desired flow rate or pressure, allowing for smooth and responsive control. Key components include:

- Actuator: Converts electrical signals into mechanical movement, adjusting the valve opening.

- Sensor: Monitors the flow or pressure and sends feedback to the controller.

- Controller: Processes the input signal and regulates the actuator’s movement.

Benefits of High-Precision Proportional Valves

- Enhanced Control: Allows for precise adjustments to flow and pressure, improving overall system performance.

- Increased Efficiency: Optimizes energy consumption by ensuring that only the necessary amount of fluid is used.

- Improved Response Time: Provides faster adjustments to changing conditions, enhancing system reliability.

- Reduced Wear and Tear: Minimizes the stress on components by preventing abrupt changes in flow and pressure.

Festo’s Innovative Approach

Overview of Festo

Festo is know for its pioneering innovations in automation technology, providing solutions that enhance productivity and efficiency in industrial applications. With a commitment to quality and innovation, Festo continuously develops cutting-edge products that meet the evolving needs of the market.

Introduction of the High-Precision Proportional Valve Terminal

Festo’s new high-precision proportional valve terminal is a game-changer in the world of pneumatic control. This terminal integrates advanced features and technologies that set it apart from conventional valve systems:

- Modular Design: The valve terminal’s modular architecture allows for flexible configurations, enabling users to customize their systems based on specific application requirements.

- Digital Connectivity: Enhanced connectivity options facilitate seamless integration with existing automation systems, making it easier to implement in various setups.

- Smart Technology: Equipped with intelligent sensors and control algorithms, the valve terminal provides real-time monitoring and adjustments, ensuring optimal performance.

- User-Friendly Interface: The terminal is design with an intuitive interface, simplifying setup and operation for users.

Applications of High-Precision Proportional Valve Terminals

The introduction of Festo’s high-precision proportional valve terminal opens up new applications across multiple industries:

1. Automotive Industry

In automotive manufacturing, precision control is essential for processes such as painting, assembly, and testing. The valve terminal can regulate the flow of paint or air, ensuring uniform application and reducing waste.

2. Food and Beverage

In food processing, maintaining strict hygiene and quality standards is critical. High-precision proportional valves can control the flow of liquids and gases in packaging and processing, ensuring consistency and compliance with safety regulations.

3. Pharmaceuticals

In the pharmaceutical industry, precise control over fluid handling is crucial. The valve terminal can facilitate accurate dosing and mixing of compounds, ensuring product quality and efficacy.

4. Manufacturing and Automation

In various manufacturing processes, the ability to control pressure and flow with precision allows for better automation and efficiency. The valve terminal can optimize processes such as CNC machining, injection molding, and more.

5. Aerospace

The aerospace industry requires the highest levels of precision and reliability. High-precision proportional valves can be useful in hydraulic systems and fuel management, ensuring safety and performance.

The Future of Pneumatic Control

The introduction of Festo’s high-precision proportional valve terminal represents a significant leap forward in pneumatic control technology. As industries continue to demand higher levels of efficiency and precision, the market for advance valve systems is expected to grow. Key trends influencing this growth include:

- Industry 4.0: The integration of IoT and smart technology in manufacturing processes is driving the demand for advanced automation solutions, including high-precision valves.

- Sustainability: As companies strive for more sustainable operations, efficient control systems that minimize waste and energy consumption will be increasingly sought after.

- Customization: The demand for tailored solutions is rising, pushing manufacturers to develop modular and adaptable systems that can be easily configure for different applications.

Challenges and Considerations

While the introduction of high-precision proportional valve terminals presents numerous opportunities, there are challenges that must be address:

- Integration Complexity: Integrating new technologies with existing systems can pose challenges, requiring careful planning and execution.

- Cost Factors: The initial investment for advanced valve systems may be higher compare to traditional options, although the long-term savings from increased efficiency can offset this.

- Technical Expertise: As systems become more sophisticated, the need for skilled personnel to operate and maintain them increases, necessitating ongoing training and development.

Conclusion

Festo’s introduction of the high-precision proportional valve terminal marks a significant advancement in pneumatic control technology. By enabling greater accuracy and control, this innovation is set to revolutionize a range of industries, from automotive to pharmaceuticals. As the demand for efficient and precise solutions continues to grow, Festo is well-position to lead the charge in the evolving landscape of industrial automation.

FAQs

- What is a high-precision proportional valve? A high-precision proportional valve is a device that regulates fluid flow and pressure with high accuracy, allowing for smooth and responsive control.

- What industries benefit from high-precision proportional valves? Industries such as automotive, food and beverage, pharmaceuticals, manufacturing, and aerospace benefit significantly from these valves.

- How does Festo’s valve terminal differ from traditional valves? Festo’s valve terminal features a modular design, digital connectivity, smart technology, and a user-friendly interface, enhancing its flexibility and performance.

- What are the key advantages of using high-precision proportional valves? Key advantages include enhanced control, increased efficiency, improved response time, and reduced wear and tear on system components.

- What trends are influencing the pneumatic control market? Trends include the rise of Industry 4.0, a focus on sustainability, and an increasing demand for customized automation solutions.