Proportional valve play a crucial role in modern hydraulic systems, providing precise control over fluid flow and pressure. Among the various types of proportional valves, those equipped with pressure compensation technology offer enhanced performance and versatility. This article explores the mechanics, advantages, applications, and future trends related to proportional valves with pressure compensation.

Understanding Proportional Valves

What is a Proportional Valve?

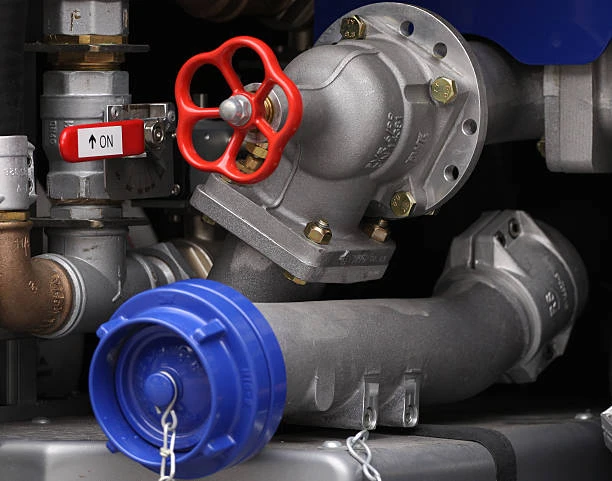

A proportional valve is an electromechanical device that regulates the flow and pressure of hydraulic fluids based on an electrical input signal. Unlike traditional on/off valves, proportional valves can modulate flow rates continuously, allowing for greater control over system operations.

Key Features of Proportional Valves

- Variable Control: Proportional valves enable continuous adjustments in flow and pressure, enhancing system responsiveness.

- Feedback Mechanisms: Many proportional valves come equipped with sensors that provide real-time feedback, ensuring optimal performance.

- Wide Range of Applications: Proportional valves are used in various industries, including manufacturing, automotive, and aerospace.

The Role of Pressure Compensation

What is Pressure Compensation?

Pressure compensation is a technology that allows proportional valves to maintain a constant flow rate, even in the presence of varying pressure conditions. This is achieved through the use of specific mechanisms that adjust the valve’s opening based on the system pressure.

How Does it Work?

When the system pressure changes, a pressure compensator within the valve automatically adjusts the valve opening. This ensures that the flow rate remains consistent, regardless of fluctuations in pressure. This feature is particularly beneficial in applications where stable operation is critical.

Advantages of Proportional Valves with Pressure Compensation

1. Enhanced System Stability

One of the primary advantages of using proportional valves with pressure compensation is improved system stability. By maintaining a constant flow rate, these valves help prevent pressure spikes that can lead to equipment damage or failure.

2. Improved Efficiency

Proportional valves with pressure compensation contribute to overall system efficiency. By ensuring that the correct flow rate is maintained, they minimize energy consumption and reduce operational costs.

3. Increased Responsiveness

These valves offer superior responsiveness to control signals. This allows for quick adjustments in flow and pressure, enhancing the performance of hydraulic systems in dynamic applications.

4. Reduced Wear and Tear

By stabilizing flow rates and minimizing pressure fluctuations, pressure-compensated proportional valves reduce wear and tear on hydraulic components. This leads to longer equipment life and reduced maintenance costs.

Applications of Proportional Valves with Pressure Compensation

1. Industrial Automation

In industrial automation systems, proportional valves with pressure compensation are used to control actuators and cylinders. Their ability to maintain stable flow rates ensures consistent performance in tasks such as material handling, assembly, and packaging.

2. Mobile Equipment

In mobile machinery, such as excavators and forklifts, these valves play a critical role in ensuring smooth operation. They provide the necessary control for hydraulic functions, improving safety and efficiency.

3. Aerospace

The aerospace industry relies on proportional valves with pressure compensation for precise control in hydraulic systems. Their ability to maintain stable performance under varying conditions is essential for safety and reliability.

4. Oil and Gas

In oil and gas applications, these valves are utilized for flow control in drilling and extraction processes. Their robustness and efficiency make them ideal for challenging environments.

Future Trends in Proportional Valve Technology

Increased Digitalization

As industries move towards smart manufacturing, proportional valves with pressure compensation are likely to become more digitally integrated. Advanced sensors and IoT connectivity will enable real-time monitoring and adjustments, further enhancing performance.

Sustainability Focus

The growing emphasis on sustainability will drive innovations in proportional valve technology. Future designs will prioritize energy efficiency, reducing the environmental impact of hydraulic systems.

Customization

As industries seek more tailored solutions, manufacturers will focus on customizing proportional valves to meet specific application needs. This will include the integration of advanced features such as adaptive control and predictive maintenance.

Conclusion

Proportional valves with pressure compensation are essential components in modern hydraulic systems, offering enhanced stability, efficiency, and responsiveness. Their wide range of applications and advantages make them invaluable in various industries, from manufacturing to aerospace. As technology advances, the future of proportional valves looks promising, with digitalization and sustainability driving innovation and development.

FAQs

- What is the primary function of a proportional valve?

- Proportional valves regulate the flow and pressure of hydraulic fluids based on an electrical input signal, allowing for precise control.

- How does pressure compensation work in proportional valves?

- Pressure compensation adjusts the valve opening to maintain a constant flow rate, even when system pressure varies.

- What are the benefits of using proportional valves with pressure compensation?

- Benefits include enhanced system stability, improved efficiency, increased responsiveness, and reduced wear and tear on components.

- In which industries are these valves commonly useful?

- They are commonly useful in industrial automation, mobile equipment, aerospace, and oil and gas applications.

- What trends are influencing the future of proportional valve technology?

- Trends include increased digitalization, a focus on sustainability, and greater customization to meet specific application needs.