A leading valve manufacturer and pump producer has announced plans to expand its operations in Henrico, Virginia. This strategic move highlights the growing demand for advanced fluid control technologies and underscores Henrico’s position as a hub for industrial innovation. The expansion promises economic benefits for the region, increased job opportunities, and advancements in valve manufacturing.

In this article, we’ll delve into the significance of valve manufacturers in industrial applications, details of the Henrico expansion, and its potential impact on the local economy and global markets.

The Role of Valve Manufacturers in Industry

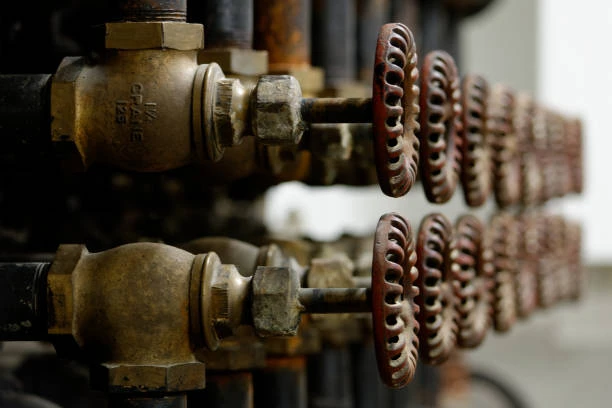

Valve manufacturers play a critical role in multiple sectors, including water management, energy production, manufacturing, and chemical processing. High-quality valves ensure safety, efficiency, and reliability in fluid control systems.

Key Functions of Valves:

- Flow Control: Regulate the movement of liquids, gases, and slurries within pipelines.

- Pressure Management: Maintain optimal pressure levels to ensure system safety.

- Shutoff Capability: Provide a secure seal to prevent leaks or contamination.

- Process Efficiency: Enable precise control over industrial processes.

The Henrico-based valve manufacturer specializes in producing custom solutions for these industries, emphasizing durability, efficiency, and technological innovation.

Expansion in Henrico: A Strategic Move

Details of the Expansion

The valve manufacturer plans to establish a state-of-the-art facility in Henrico, doubling its production capacity and introducing advanced manufacturing technologies.

Key Features of the Expansion:

- New Manufacturing Facility: A 100,000-square-foot facility equipped with cutting-edge machinery.

- Job Creation: Over 200 new positions across engineering, production, and administration.

- Innovation Hub: A dedicated research and development (R&D) center for designing next-generation valves and pumps.

Why Henrico?

Henrico offers a strategic location with access to skilled labor, a robust transportation network, and proximity to key markets. Additionally, local government incentives and a business-friendly environment have made Henrico an attractive choice for industrial growth.

Economic and Community Impact

The valve manufacturer’s expansion will deliver substantial benefits to Henrico and beyond.

1. Economic Growth

The new facility will boost Henrico’s economy by creating jobs, increasing local tax revenue, and supporting nearby businesses. The influx of skilled workers will further enhance the region’s industrial capabilities.

2. Sustainability Initiatives

The manufacturer has committed to implementing sustainable practices, such as energy-efficient production methods and waste reduction programs, aligning with Henrico’s environmental goals.

3. Community Investment

The company plans to partner with local educational institutions to develop training programs, ensuring a steady pipeline of skilled labor while fostering community development.

Advancements in Valve Manufacturing

As industries evolve, so do the demands for high-performance valves. The expanded facility in Henrico will focus on producing valves that meet the requirements of modern industrial systems.

1. Smart Valves for Industry 4.0

Smart valves equipped with IoT sensors enable real-time monitoring and remote control, improving system efficiency and reducing downtime.

2. Custom Valve Solutions

The manufacturer specializes in designing custom valves tailored to specific applications, ensuring optimal performance in diverse environments.

3. Sustainable Materials

Using eco-friendly materials and production techniques, the manufacturer aligns its products with global sustainability standards.

Challenges and Solutions

Challenges

- Initial Installation Costs:

- While the upfront cost of installing a backflow valve can be significant, Ottawa’s incentive program helps offset this expense.

- Maintenance Requirements:

- Backflow valves require periodic inspections and cleaning to function effectively.

Solutions

- Incentive Program Support:

- Financial assistance makes the installation process more accessible.

- Public Education:

- The city plans to provide guidance on maintenance and the long-term benefits of backflow prevention.

The Global Valve Market: Opportunities and Challenges

The valve industry is poised for significant growth, driven by increasing investments in infrastructure, energy, and water management. However, challenges such as supply chain disruptions and rising material costs require manufacturers to innovate and adapt.

Henrico as a Global Player

With its expanded operations, the valve manufacturer aims to strengthen its position in global markets, leveraging Henrico’s strategic advantages to meet growing demand.

The Future of Valve Manufacturing in Henrico

The pump and valve manufacturer’s expansion is a testament to Henrico’s potential as a hub for industrial innovation. The facility will not only boost local economic growth but also set new benchmarks for valve manufacturing, combining technology, sustainability, and workforce development.

By investing in Henrico, the company positions itself as a leader in the valve manufacturing industry, ready to tackle the challenges of tomorrow while supporting the community today.

FAQs

1. What does a valve manufacturer do?

A valve manufacturer designs and produces valves used in fluid control systems across industries such as water management, energy, and manufacturing.

2. Why is the valve manufacturer expanding in Henrico?

Henrico offers access to skilled labor, excellent transportation networks, and local government incentives, making it an ideal location for industrial growth.

3. How will the expansion benefit the local community?

The expansion will create over 200 jobs, boost the local economy, and support educational and community initiatives in Henrico.

4. What advancements will the new facility focus on?

The facility will focus on smart valve technologies, custom valve solutions, and sustainable manufacturing practices.

5. What industries rely on valve manufacturers?

Industries such as water management, oil and gas, chemical processing, and manufacturing depend on valve manufacturers for efficient and reliable fluid control systems.