RWE Gas Storage West has taken a significant step toward advancing hydrogen storage technology by ordering 1,400 ball valves from Hartmann Valves for its upcoming hydrogen storage facility in Lingen, Germany. This collaboration highlights the crucial role of ball valves in hydrogen systems, where precision, durability, and safety are paramount.

The hydrogen storage facility, a key component of RWE’s transition to clean energy solutions, relies on robust infrastructure to manage the unique challenges of hydrogen handling. The use of high-quality ball valves ensures efficiency and safety in this innovative project.

The Importance of Ball Valves in Hydrogen Storage

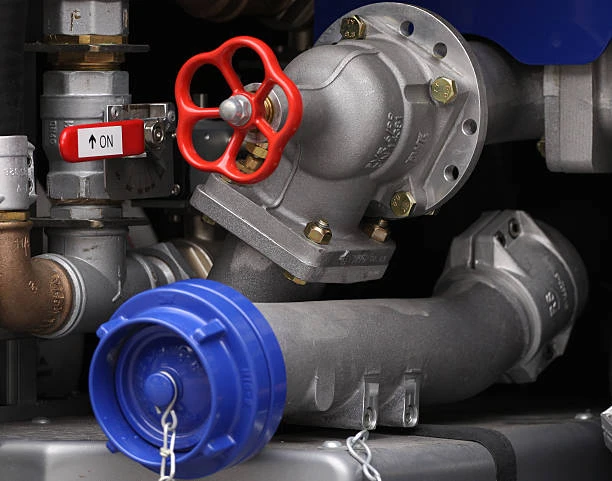

Ball valves play a critical role in controlling and regulating fluid flow in pipelines. Their spherical design allows precise operation, providing a reliable solution for applications that require high levels of safety and efficiency.

Why Ball Valves Are Ideal for Hydrogen Systems:

- Leak Prevention: Hydrogen molecules are extremely small and can escape through poorly sealed valves. Ball valves with tight seals prevent leaks.

- Durability: Hydrogen systems often operate under high pressure. Ball valves are built to withstand these conditions.

- Ease of Operation: The simple mechanism of ball valves allows quick and reliable opening or closing, essential in emergency scenarios.

- Resistance to Corrosion: Hydrogen can be reactive under certain conditions. Ball valves constructed with specialized materials resist corrosion and ensure longevity.

Overview of the Lingen Hydrogen Storage Facility

The Lingen hydrogen storage facility is part of Germany’s larger strategy to integrate renewable energy sources into its power grid. Hydrogen, produced using green energy, will be stored and distributed for industrial and energy applications.

Key Features of the Facility:

- Advanced Storage Technology: The facility will use state-of-the-art equipment, including ball valves from Hartmann Valves, to handle hydrogen safely.

- Green Energy Integration: Hydrogen will serve as a storage medium for excess renewable energy, addressing challenges associated with energy intermittency.

- Scalability: The design allows for future expansion, positioning Lingen as a cornerstone of Germany’s hydrogen economy.

Hartmann Valves’ ball valves will be integrated into the facility’s pipeline systems, ensuring efficient and secure hydrogen storage and transport.

Hartmann Valves: A Trusted Partner

The Hartmann Valves is renowned for its expertise in manufacturing high-performance ball valve for demanding applications, including hydrogen storage and transport. The company’s commitment to innovation and quality aligns perfectly with the requirements of the Lingen facility.

Features of Hartmann Valves’ Ball Valve:

- High-Pressure Resistance: Capable of operating under extreme pressure conditions, ensuring safety in hydrogen applications.

- Advanced Sealing Technology: Prevents leaks, even under challenging conditions.

- Material Compatibility: Designed with materials that resist hydrogen embrittlement, a common issue in hydrogen systems.

- Custom Solutions: Tailored designs to meet the specific needs of the Lingen facility.

The partnership underscores the importance of choosing reliable components for critical energy infrastructure projects.

Benefits of Using Ball Valve in the Hydrogen Economy

1. Enhanced Safety

Ball valve ensure tight sealing, minimizing the risk of hydrogen leaks that could lead to explosions or environmental damage.

2. Operational Efficiency

The ease of operation and reliable performance of ball valve optimize the management of hydrogen systems, reducing downtime and maintenance needs.

3. Scalability

Ball valves are adaptable to various system sizes, making them ideal for projects like Lingen, which require flexibility for future expansion.

4. Longevity

Durable materials and advanced designs ensure that ball valve perform reliably over extended periods, even in demanding environments.

The Role of Hydrogen in the Energy Transition

Hydrogen is a cornerstone of the global shift toward cleaner energy sources. Its versatility allows it to replace fossil fuels in various sectors, including transportation, industry, and power generation. Facilities like Lingen are essential for scaling up hydrogen use, and components like ball valves ensure these systems operate safely and efficiently.

RWE Gas Storage West’s investment in advanced equipment for Lingen reflects its commitment to innovation and sustainability. The use of Hartmann Valves’ ball valves represents a critical step in building the infrastructure needed for a hydrogen-based energy future.

Challenges in Hydrogen Storage and How Ball Valves Address Them

1. High Pressure and Temperature Variations

Hydrogen storage often involves extreme pressures and temperature fluctuations. Ball valves designed for these conditions ensure consistent performance.

2. Hydrogen Embrittlement

This phenomenon can weaken materials over time. Ball valve made from specialized alloys resist embrittlement, ensuring long-term reliability.

3. Leak Prevention

The small size of hydrogen molecules makes leak prevention challenging. Advanced sealing mechanisms in ball valves provide a robust solution.

Conclusion

The collaboration between RWE Gas Storage West and Hartmann Valve underscores the critical role of ball valve in the hydrogen economy. As Germany leads the way in clean energy innovation, the Lingen facility serves as a model for integrating advanced technologies into hydrogen storage systems.

By investing in high-performance ball valve, RWE ensures the safety, efficiency, and scalability of its hydrogen storage operations. This project is a testament to the importance of robust infrastructure in achieving a sustainable energy future.

FAQs

1. What makes ball valve suitable for hydrogen storage systems?

Ball valve are ideal for hydrogen systems due to their leak-proof design, high-pressure resistance, and compatibility with materials that resist hydrogen embrittlement.

2. Why did RWE choose Hartmann Valves for the Lingen facility?

Hartmann Valve is known for its high-quality ball valve, designed to meet the demanding requirements of hydrogen storage and transport systems.

3. How does the Lingen facility contribute to the hydrogen economy?

The facility stores hydrogen produced from renewable energy, providing a scalable solution for integrating green energy into industrial and power applications.

4. What challenges do hydrogen storage systems face?

Key challenges include high-pressure conditions, hydrogen embrittlement, and the need for leak prevention, all of which require advanced equipment like ball valve.

5. What is hydrogen embrittlement, and how do ball valve address it?

Hydrogen embrittlement is the weakening of materials due to hydrogen exposure. Ball valve made with resistant alloys prevent this issue, ensuring long-term durability.