Introduction

The push for sustainability in construction and plumbing has brought significant attention to the use of recycled materials. Among these, recycled PPR (Polypropylene Random Copolymer) pipes are emerging as a leading solution for modern plumbing needs. This article explores the successful reform involving recycled PPR Pipe, highlighting their advantages, applications, and the impact on the environment and the economy.

Understanding PPR Pipe

PPR pipes are renowned for their durability, resistance to corrosion, and lightweight nature. These properties make them ideal for a wide range of applications, from residential plumbing to industrial systems.

1. Characteristics of PPR Pipe

- Durability: PPR pipes have a lifespan of over 50 years, significantly reducing the need for frequent replacements.

- Temperature Resistance: They can handle temperatures ranging from -40°C to 95°C, making them suitable for both hot and cold water systems.

- Chemical Resistance: PPR pipes resist many chemicals, making them ideal for various industrial applications.

The Shift to Recycled PPR Pipe

1. Why Recycle PPR Pipe?

The recycling of PPR pipes addresses both environmental concerns and resource scarcity. As awareness of plastic waste grows, the demand for recycled materials in construction is increasing.

2. Benefits of Recycled PPR Pipe

- Reduced Environmental Impact: Recycling helps divert plastic waste from landfills and reduces the carbon footprint associated with new pipe production.

- Cost Efficiency: Recycled materials often come at a lower cost than virgin materials, providing economic benefits for manufacturers and consumers.

- Resource Conservation: Using recycled PPR pipes conserves natural resources and reduces the demand for fossil fuels used in the production of new plastics.

The Recycling Process

The recycling process for PPR pipes involves several key steps to ensure the production of high-quality recycled materials.

1. Collection and Sorting

Used PPR pipes are collected and sorted to remove contaminants such as dirt, metal fittings, and other non-PPR materials. This step is crucial to ensure the purity of the recycled product.

2. Shredding and Washing

Once sorted, the pipes are shredde into smaller pieces and thoroughly washed to eliminate any residual contaminants. This process prepares the material for further processing.

3. Extrusion and Pelletization

The cleaned and shredded PPR is then melted and extruded to form pellets. These pellets can be use to manufacture new PPR pipes, maintaining the quality and properties of the original material.

Successful Applications of Recycled PPR Pipe

Recycled PPR pipes have found various applications across different sectors, showcasing their versatility and effectiveness.

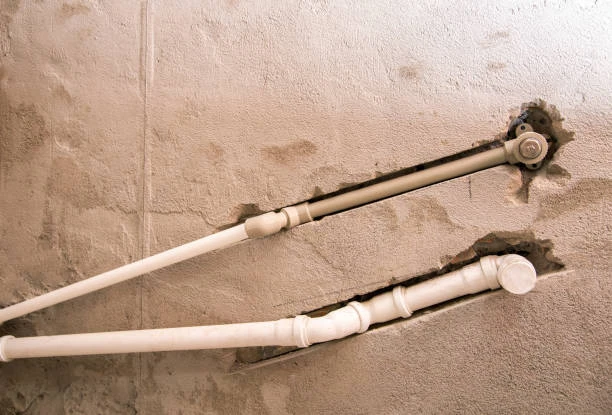

1. Residential Plumbing

In residential construction, recycled PPR pipes are increasingly use for water supply lines and drainage systems. Their durability and reliability make them an attractive option for homeowners looking for sustainable plumbing solutions.

2. Industrial Applications

Many industries have begun adopting recycled PPR pipes for chemical transport and wastewater management. Their resistance to corrosion and chemicals makes them suitable for demanding environments.

3. Infrastructure Projects

Governments and municipalities are turning to recycled PPR pipes for public infrastructure projects, such as water distribution networks and irrigation systems. This shift supports sustainability goals while ensuring efficient water management.

Case Studies of Successful Reforms

Several successful case studies illustrate the benefits of using recycled PPR pipes in various projects.

1. Urban Housing Projects

In a recent urban housing project, developers opted for recycled PPR pipes for the plumbing system. This choice not only reduced material costs but also contributed to the project’s sustainability certification, attracting environmentally conscious buyers.

2. Industrial Plant Upgrades

An industrial plant upgraded its water supply system using recycled PPR pipes, leading to a significant reduction in maintenance costs due to the material’s durability. The project also garnered positive attention for its commitment to sustainability.

Challenges in Implementing Recycled PPR Pipe

While the benefits are substantial, several challenges exist in the widespread adoption of recycled PPR pipes.

1. Quality Assurance

Ensuring that recycled PPR pipes meet industry standards can be challenging. Manufacturers must invest in quality control processes to guarantee the reliability of their products.

2. Market Perception

Some consumers may still hold misconceptions about the quality of recycled materials. Educating the market on the advantages and performance of recycled PPR pipes is crucial for broader acceptance.

3. Regulatory Hurdles

Navigating regulatory frameworks for recycled materials can be complex. Manufacturers need to stay updated on guidelines to ensure compliance while promoting their products.

The Future of Recycled PPR Pipe

The future of recycled PPR pipes looks promising, with several trends likely to shape the market.

1. Technological Advancements

As technology continues to advance, the recycling process for PPR pipes will likely become more efficient, resulting in higher-quality recycled products and lower production costs.

2. Growing Demand for Sustainable Solutions

With an increasing focus on sustainability, the demand for recycled materials, including PPR pipes, is expect to rise. This trend will encourage more manufacturers to adopt recycling practices.

3. Increased Collaboration

Collaboration between manufacturers, government agencies, and environmental organizations can help promote the benefits of recycled PPR pipes, fostering innovation and expanding market reach.

Conclusion

The successful reform with recycled PPR Pipe represents a significant step towards sustainability in the plumbing industry. With their numerous advantages, including durability, cost efficiency, and reduced environmental impact, recycled PPR pipes are poised to become a staple in modern construction and industrial applications. By addressing challenges and embracing innovation, the industry can fully leverage the benefits of recycled materials for a greener future.

FAQs

- What are PPR pipes made of?

- PPR pipes are made from polypropylene random copolymer, known for its durability and resistance to chemicals.

- How are PPR pipes recycled?

- PPR pipes are collected, sorted, shredded, washed, and then melted to form pellets, which are used to manufacture new pipes.

- What are the advantages of using recycled PPR pipes?

- Recycled PPR pipes are environmentally friendly, cost-effective, and conserve natural resources, while still maintaining quality.

- Are recycled PPR pipes as durable as new ones?

- Yes, recycled PPR pipes can be manufactured to meet the same quality and durability standards as new pipes.

- What applications are suitable for recycled PPR pipes?

- Recycled PPR pipes are suitable for residential plumbing, industrial applications, and public infrastructure projects.