Introduction PPR Pipe

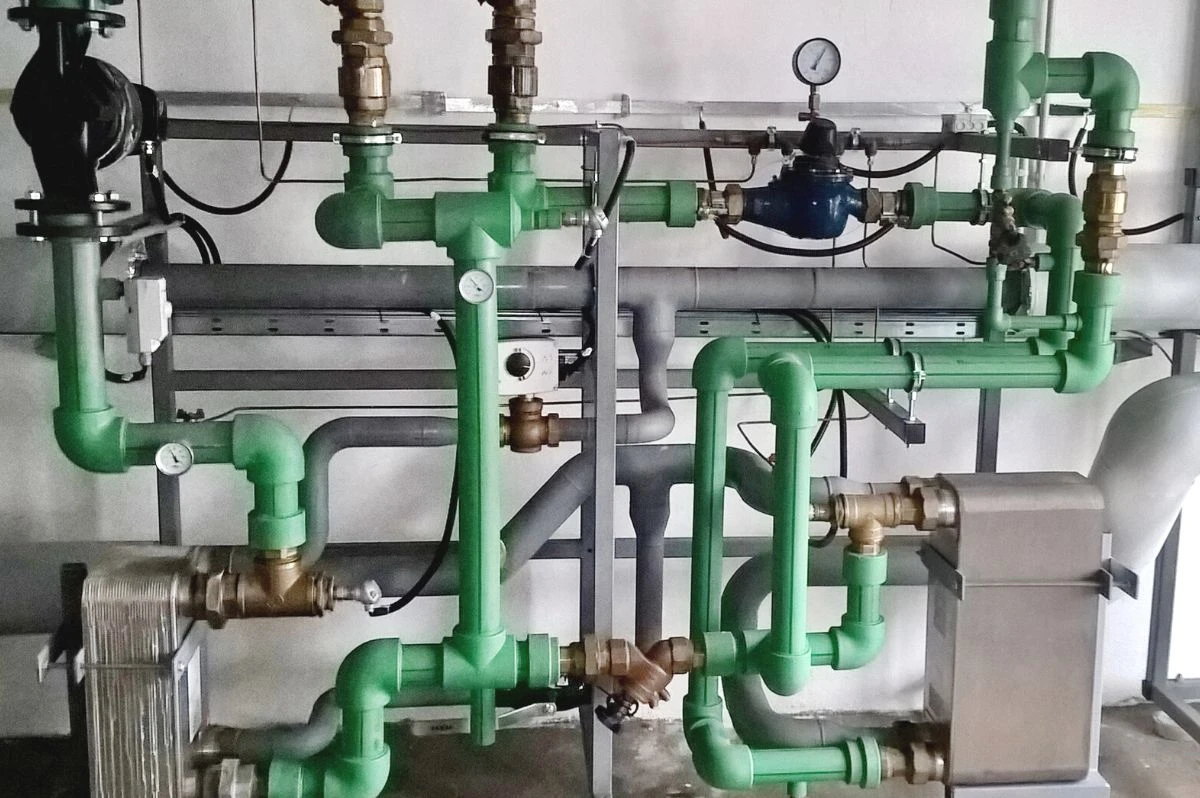

PPR Pipe (Polypropylene Random Copolymer pipes) have long been a staple in plumbing systems across Western Australia (WA). Known for their durability, resistance to corrosion, and overall performance, these pipes are commonly used in both residential and commercial projects. However, recent reports have raised concerns about a growing number of defective PPR pipes, causing significant problems for homeowners, contractors, and the environment.

These defects have triggered debates about the quality of materials used in construction and the standards of manufacturing and installation practices. With construction costs rising and plumbing issues becoming more common, understanding the root causes of defective PPR pipes in WA is critical. In this article, we’ll explore the potential causes, risks, and solutions to the growing problem of defective PPR pipes.

What Are PPR Pipe?

PPR pipes are a type of plastic piping commonly used in plumbing systems for both hot and cold water distribution. They are made from polypropylene, a durable and flexible material that resists corrosion, scaling, and the harsh chemicals often found in water. This makes PPR pipes highly resistant to wear and tear, which is one of the reasons they have become so popular in modern plumbing systems.

Common Uses in Plumbing PPR pipes are typically used in:

- Residential water supply systems

- Commercial plumbing installations

- Heating systems and air conditioning units

- Industrial pipelines for chemicals and water treatment

Advantages of PPR Pipe

- Durability: PPR pipes can last for decades with proper installation.

- Resistance to Corrosion: They do not rust or degrade when exposed to water.

- Ease of Installation: The pipes are light and easy to work with.

- Energy Efficiency: PPR pipes are resistant to heat loss, making them ideal for both hot and cold water systems.

Despite these advantages, there has been an alarming increase in reports of defective PPR pipes in WA, raising serious concerns about their reliability and the safety of plumbing systems.

The Rise in Defective PPR Pipe in WA

In recent months, numerous reports have surfaced about defective PPR pipes causing issues in plumbing systems across Western Australia. Homeowners and contractors have experienced problems ranging from water leaks to complete system failures due to defective pipes. In some cases, defects have led to severe property damage, costly repairs, and delays in construction projects.

Local authorities are beginning to investigate these issues, and many are calling for greater scrutiny of the manufacturing processes and installation practices associated with PPR pipes.

Causes of Defective PPR Pipe

Defective PPR pipes are not a result of just one factor; several elements can contribute to their failure:

- Manufacturing Defects Some defects arise during the manufacturing process. These could include poor material quality, improper molding, or contamination during production. Pipes that don’t meet proper industry standards are more likely to fail when exposed to high-pressure systems or fluctuating temperatures.

- Poor Installation Practices Improper installation is another leading cause of defective PPR pipes. Inexperienced or negligent plumbers might use the wrong fittings or fail to secure joints properly, leading to leaks or pipe breaks.

- Environmental Factors Extreme weather conditions or exposure to UV light over long periods can degrade the quality of PPR pipes. Prolonged exposure to the sun can cause the material to become brittle, increasing the risk of cracks and leaks.

Impact on Construction and Plumbing Projects

Defective PPR pipes can have a significant impact on both construction projects and existing plumbing systems:

- Project Delays and Costs: If defective pipes are discovered after installation, construction projects can face delays as pipes need to be replaced. This not only adds unexpected costs but can also lead to disputes between contractors, suppliers, and clients.

- Safety Hazards: Defective pipes can pose serious safety risks, such as water contamination or burst pipes. In extreme cases, they could lead to structural damage, fire hazards, or health concerns.

- Decreased Water Quality and Efficiency: Cracks or leaks in defective PPR pipes can allow contaminants to enter the water supply, leading to poor water quality. In some cases, the water supply could be shut off entirely until the issue is fixed.

Signs and Symptoms of Defective PPR Pipe

Homeowners and plumbers should be on the lookout for the following signs that may indicate defective PPR pipes:

- Cracks and Leaks: Visible cracks or leaks near pipe joints can be a clear sign that the pipes are defective.

- Decreased Water Flow: If there’s a noticeable drop in water pressure or flow, this could indicate internal damage.

- Discoloration of Water: If your water turns an unusual color, it may be a result of pipe degradation or contamination from the defective piping.

- Unusual Odors or Tastes: If the water has a strange taste or smell, it may be a sign that the pipes are failing, and contaminants are leaking into the system.

How Defective PPR Pipe Can Affect the Environment

The environmental impact of defective PPR pipes should not be underestimated:

- Waste of Water Resources: Leaks and cracks in PPR pipes result in wasted water, contributing to water shortages, especially in areas already facing droughts or water scarcity.

- Potential Environmental Damage: Leaks, especially those near sewer systems or chemical pipelines, can cause contamination of local ecosystems. In the worst-case scenario, harmful chemicals could leak into water supplies, posing risks to wildlife and plant life.

- Long-Term Effects: Over time, defective PPR pipes can cause soil erosion, degrade landscaping, and even lead to the contamination of natural water sources if left unchecked.

Regulatory Standards and Safety Measures

To ensure the safety and quality of plumbing systems, PPR pipes must meet specific industry standards. In WA, the government and regulatory bodies work closely with manufacturers to ensure pipes meet quality and safety requirements.

- National and International Standards: PPR pipes are subject to stringent standards set by organizations like ISO and Australian standards for plumbing and building materials.

- Regulatory Inspections: In WA, plumbing installations must pass local inspection codes before they are approved for use. This ensures that any defective pipes are identified early in the construction process.

What to Do If You Suspect Defective PPR Pipe

If you suspect your PPR pipes may be defective, here’s what you can do:

- Inspect the Pipes: Look for visible signs of damage like cracks, discoloration, or leaks.

- Consult a Professional: Have a licensed plumber or contractor inspect the system. They can identify any faults and provide the best solution.

- Document the Damage: Keep records of any issues you find, as this may be needed for warranty claims or legal purposes.

How to Prevent Defective PPR Pipe Issues

While defective pipes can be frustrating, there are steps you can take to prevent issues:

- Buy from Reputable Manufacturers: Choose pipes from established brands with a history of quality control and certifications.

- Proper Installation: Hire experienced professionals to ensure the pipes are installed correctly, following all safety and installation guidelines.

- Routine Maintenance: Regularly check and maintain your plumbing system to catch any potential issues early before they escalate.

The Role of Quality Control in Preventing Defects

Quality control plays a crucial role in ensuring the longevity and safety of PPR pipes. Manufacturers must follow strict quality checks throughout the production process to ensure that every batch of pipes meets industry standards. Improved technology and automated systems are helping to reduce defects and increase the consistency of product quality.

Recent Legal Cases and Consequences in WA

Defective PPR pipes have led to legal cases in WA, with some manufacturers and contractors being held accountable for their role in producing or installing faulty pipes. These cases serve as a reminder of the importance of quality in construction and plumbing and highlight the need for stronger regulations and consumer protections.

Consumer Awareness: How to Identify Quality PPR Pipe

Consumers must be diligent when purchasing PPR pipes. Look for:

- Certifications and Product Labels from trusted regulatory bodies.

- Brand Reputation: Opt for well-known brands with a history of reliable products.

- Visual Inspection: Ensure the pipes have no visible cracks, discoloration, or deformities before purchasing.

Industry Response and Solutions to the Issue

The PPR pipe industry is addressing the growing concern by:

- Introducing better quality control measures during manufacturing.

- Improving pipe design and materials for increased durability.

- Offering warranties to protect consumers from defective products.

Conclusion

The rise in defective PPR pipes in WA is a serious issue that affects both residential and commercial plumbing systems. While PPR pipes offer numerous advantages, it’s essential to ensure that the products are of high quality, installed properly, and maintained regularly. By being proactive and vigilant, consumers can help prevent many of the issues associated with defective pipes.

As the industry works to improve quality control and manufacturing standards, it’s important for homeowners and businesses in WA to stay informed and take necessary precautions to avoid plumbing problems caused by defective PPR pipes.

FAQs

- What is the lifespan of a PPR pipe?

PPR pipes typically last 50 years or more when installed and maintained correctly. - How can I tell if my PPR pipes are defective?

Look for cracks, leaks, discoloration, or reduced water flow, as these are common signs of defective pipes. - Are defective PPR pipes covered under warranty?

Yes, many manufacturers offer warranties for PPR pipes. Check with your supplier for specific coverage. - Can I replace PPR pipes myself?

It’s recommended to hire a professional plumber to replace defective PPR pipes to ensure safety and proper installation. - How can defective PPR pipes impact my water supply?

Defective pipes can lead to water contamination, reduced pressure, or even complete water loss, affecting your plumbing system’s functionality.