1. Application Type PPR Fittings Mould

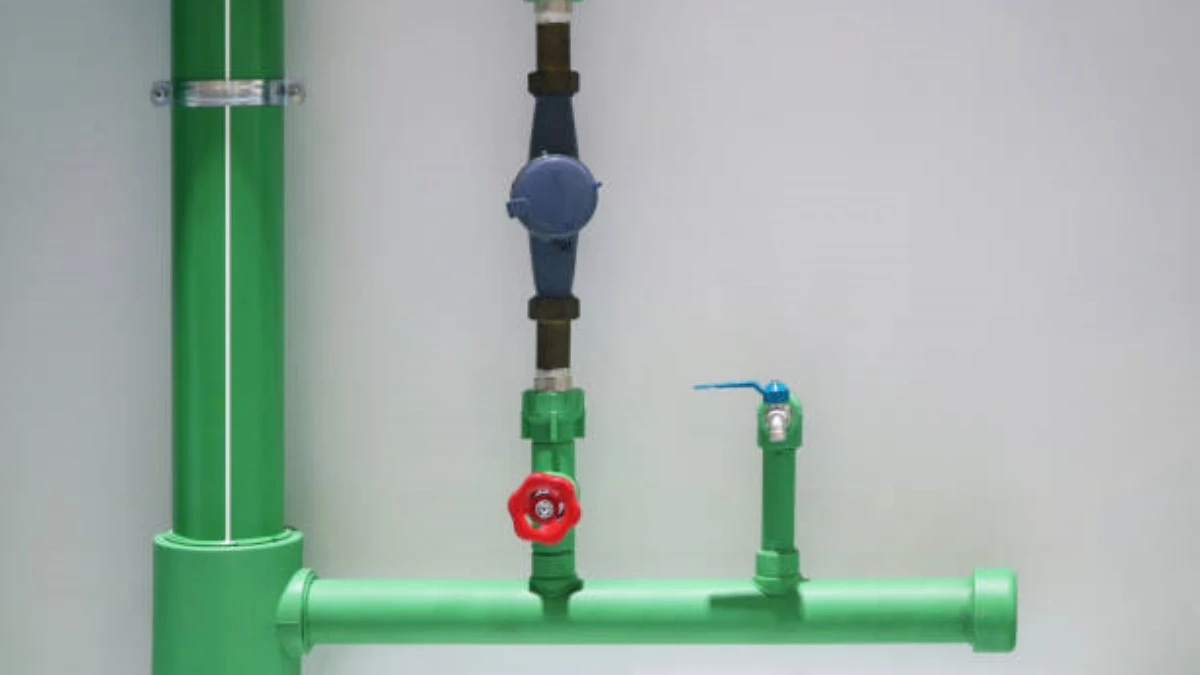

Start by identifying the specific application for which you require ppr fittings mould. Different applications may demand different types of fittings. For instance, residential plumbing may only require standard fittings for hot and cold water systems. In contrast, industrial applications may need specialized fittings that can handle higher pressures and temperatures.

Choose fittings designed for your specific application to ensure optimal performance and safety.

2. Pipe Diameter PPR Fittings Mould

PPR fittings come in various diameters to fit different pipe sizes. When selecting fittings, measure the diameter of the pipes you plan to use. Common sizes include 20mm, 25mm, 32mm, and 63mm, among others.

Using the correct diameter ensures a tight fit and prevents leaks. Always double-check measurements before making a purchase.

3. Temperature Resistance PPR Fittings Mould

PPR fittings can handle a wide range of temperatures. Standard PPR fittings typically withstand temperatures up to 95°C (203°F), making them suitable for hot water systems. If your application involves higher temperatures or extreme conditions, look for specialized PPR fittings that offer enhanced heat resistance.

Understanding your system’s temperature requirements helps you choose the right fittings to prevent deformation or failure.

4. Pressure Ratings PPR Fittings Mould

Consider the pressure ratings of your PPR fittings. Different fittings can handle varying levels of pressure, and it’s essential to choose fittings that match the pressure requirements of your plumbing system.

For example, if you plan to use PPR fittings in a high-pressure environment, ensure the selected fittings can withstand those conditions. Always consult manufacturer specifications for accurate pressure ratings.

5. Quality and Standards PPR Fittings Mould

When choosing PPR fittings, prioritize quality and compliance with industry standards. Look for fittings that meet national and international quality certifications. High-quality fittings ensure reliability and longevity in your plumbing system.

Reputable manufacturers often provide certifications that guarantee their products meet specific performance criteria. Investing in quality fittings saves you money in the long run by reducing the need for replacements.

6. Installation Method PPR Fittings Mould

Different PPR fittings may require various installation methods. Most PPR fittings use heat fusion for secure connections, while others may use threaded or mechanical connections.

If you choose heat fusion fittings, ensure you have the necessary tools, like a welding machine and pipe cutter. Familiarize yourself with the installation process to avoid mistakes that could lead to leaks.

7. Cost Considerations PPR Fittings Mould

While it is essential to invest in quality PPR fittings, keep your budget in mind. Prices can vary significantly based on the type, size, and brand of fittings. However, opting for the cheapest option might lead to poor performance and higher maintenance costs over time.

Aim for a balance between quality and affordability. Research different suppliers to find competitive prices without compromising on quality.

8. Compatibility with Existing Systems

If you are integrating PPR fittings into an existing plumbing system, ensure compatibility with the current materials and components. Mixing different types of fittings and pipes can lead to leaks and system failures.

If your existing system uses PVC, copper, or other materials, consult a plumbing professional to determine the best way to integrate PPR fittings.

Common Types of PPR Pipe Fittings

Understanding the various types of PPR fittings available can help you make informed decisions. Here are some common types:

1. Elbow Fittings

Elbow fittings allow for directional changes in the piping system. They come in various angles, such as 90 degrees and 45 degrees, and help navigate around obstacles in plumbing installations.

2. Tee Fittings

Tee fittings create branches in the plumbing system. They connect three pipes, allowing for a main line to split into two separate lines, which is particularly useful in complex plumbing layouts.

3. Couplings

Couplings are used to connect two straight sections of pipe. They come in various sizes and allow for easy extensions or repairs in the piping system.

4. End Caps

End caps seal the end of a pipe, preventing water flow. They are useful for terminating a line or closing off unused connections.

5. Reducers

Reducers connect pipes of different diameters. They allow for a smooth transition between larger and smaller pipes, ensuring efficient water flow.

Conclusion

Choosing the right PPR pipe fittings for your plumbing system involves careful consideration of various factors, including application type, pipe diameter, temperature resistance, and pressure ratings. By understanding these aspects, you can ensure that your plumbing system operates efficiently and lasts for many years.

Invest in quality fittings that meet industry standards, and always prioritize compatibility with your existing systems. With the right PPR fittings, you can create a reliable and effective plumbing network that meets your needs.

FAQs

- What are PPR fittings?

PPR fittings are components made from polypropylene random copolymer, used to connect and direct PPR pipes in plumbing systems. - How do I know which size PPR fitting to choose?

Measure the diameter of your pipes and select fittings that match those measurements for a secure fit. - Can PPR fittings be used for hot water systems?

Yes, PPR fittings can handle hot water and withstand temperatures up to 95°C, making them suitable for such applications. - What installation tools do I need for PPR fittings?

You will need a PPR pipe cutter, a welding machine for heat fusion, and measuring tools for accurate installation. - How long do PPR fittings last?

PPR fittings can last over 50 years with proper installation and maintenance, making them a durable choice for plumbing systems.