Introduction PPR Pipe

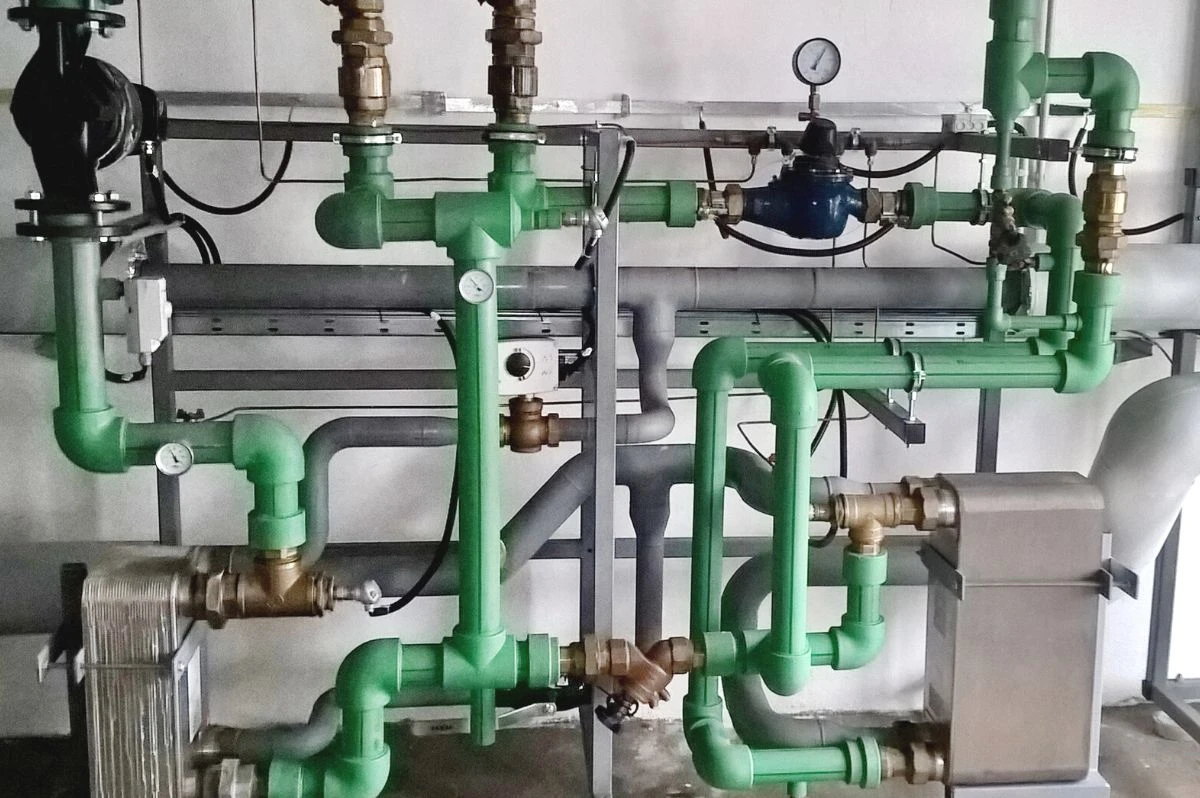

PPR Pipe (Polypropylene Random Copolymer pipes) have gained significant popularity in the plumbing and construction industry due to their durability, resistance to corrosion, and long lifespan. However, like any material, PPR pipes can encounter issues over time, such as leaks, cracks, or blockages. The process of repairing PPR pipes is crucial to maintaining an efficient and functional plumbing system. Fortunately, the advancements in PPR pipe repair techniques not only help in restoring the system’s functionality but also save both time and costs when repairing these pipes.

In this article, we will explore how modern repair methods for PPR pipes are cost-effective, time-efficient, and reliable. We will also discuss the best tools, methods, and techniques for repairing PPR pipes, ensuring that you can handle any potential issues without the need for extensive professional help. Let’s dive deeper into the world of PPR pipe repair.

Understanding PPR Pipe: A Quick Overview

Before we dive into repair techniques, it’s important to understand what makes PPR pipes so popular and why they may need repair in the first place.

What are PPR Pipe?

PPR pipes are made from a type of plastic that is highly resistant to heat and pressure. They are used for a variety of plumbing applications, including hot and cold water systems, heating systems, and even industrial applications. PPR pipes are known for their long lifespan, often exceeding 50 years, and their ability to withstand temperatures ranging from -10°C to 95°C.

Common Issues with PPR Pipe

While PPR pipes are incredibly durable, they can still face some common issues, including:

- Cracking: This can happen due to physical damage or extreme temperature fluctuations.

- Leakage: Often caused by faulty installation or wear and tear over time.

- Blockages: Can occur due to debris or sediment buildup.

- Joint Failures: Improper fusion during installation or aging can lead to joint separations.

Why Repairing PPR Pipe Saves Time and Costs

1. Cost-Effective Solutions

Repairing PPR pipes is significantly more cost-effective than replacing them entirely. Replacing a section of the piping system can involve a lot of unnecessary costs such as material, labor, and time. In many cases, simply repairing the pipe or replacing a joint can restore the system’s functionality without incurring hefty expenses.

Modern repair kits for PPR pipes are widely available, and they come with all the necessary tools for efficient repairs, from fusion welding machines to pipe cutters. These kits are affordable and often designed for DIY repairs, allowing homeowners and professionals to fix the issue without calling in expensive plumbers.

2. Quick and Efficient Repairs

When repairing PPR pipes, time is of the essence. A repair that involves cutting and replacing a faulty section of pipe can often be done within an hour. Thanks to new tools and methods, repairing PPR pipes is a relatively quick and straightforward process. For instance, with the use of fusion welding, PPR pipe repairs can be completed in a matter of minutes, minimizing downtime and inconvenience.

3. Avoiding Full System Replacement

One of the biggest benefits of PPR pipe repair is the ability to avoid a full system replacement. If a particular section of pipe or joint is damaged, there’s no need to replace the entire plumbing system. Simple repairs can restore the system to full functionality without the need for extensive work. This is especially beneficial in larger plumbing systems where replacing pipes could be a highly disruptive and expensive process.

Popular Methods for Repairing PPR Pipe

There are several methods that can be used to repair PPR pipes, depending on the nature and severity of the damage. Below, we’ll discuss the most common repair techniques used for PPR pipe systems.

1. Pipe Welding (Fusion Welding)

Fusion welding is the most common and reliable method for repairing PPR pipes. This process involves heating the ends of the pipes and then fusing them together. The two sections of pipe are heated until they become soft, then pressed together to form a permanent bond.

Advantages:

- Strong and durable connection

- Works for both pipe-to-pipe and pipe-to-fitting repairs

- Suitable for all sizes of PPR pipes

Fusion welding requires a specialized welding machine, but these are available for DIY use and can save a considerable amount of money compared to hiring a professional.

2. Compression Fittings

Compression fittings are another popular solution for PPR pipe repairs, particularly when dealing with joints that have failed. These fittings are applied to the exterior of the pipe and tightened with a wrench, creating a secure, leak-proof connection.

Advantages:

- Easy to install

- Does not require welding equipment

- Can be used in situations where welding is not feasible (e.g., in confined spaces)

Compression fittings offer a quick solution, although they may not provide the same level of long-term durability as fusion welding.

3. Epoxy and Sealant

For smaller leaks or cracks, using an epoxy or a sealant can be a temporary solution until a more permanent repair is done. These materials work by filling in the gaps or cracks and sealing the leak.

Advantages:

- Quick and easy to apply

- Affordable

- Useful for temporary fixes

However, this method is generally not recommended for larger cracks or long-term repairs as it may not provide a permanent solution.

4. Replacement of Damaged Sections

If a section of the pipe is severely damaged, it may be necessary to replace it altogether. This can be done by cutting out the damaged portion and installing a new section using fusion welding or compression fittings.

Advantages:

- Provides a permanent solution for severely damaged pipes

- Can restore the entire system to full functionality

While this method is more time-consuming and expensive than others, it ensures that the problem is resolved permanently.

Tools Required for PPR Pipe Repair

To successfully repair PPR pipes, certain tools are required. These tools can vary depending on the repair method chosen, but here are the basic tools needed for common PPR pipe repairs:

- Pipe Cutter: Used for cutting the PPR pipe cleanly and accurately.

- Fusion Welding Machine: A specialized tool for joining PPR pipes through fusion welding.

- Compression Fittings: Used to create a seal around the pipe and restore functionality.

- Epoxy/Sealant: Used to temporarily seal small cracks or leaks.

- Wrench or Spanner: For tightening compression fittings.

- Pipe Reamer: To smooth and prepare the pipe edges before joining them.

With these tools, most common PPR pipe repairs can be completed with ease.

Preventative Maintenance for PPR Pipe

To minimize the need for repairs, regular maintenance is essential. Here are some tips for keeping your PPR pipe system in good condition:

- Monitor Water Pressure: Ensure that the water pressure is not too high, as this can stress the pipes and cause damage over time.

- Avoid Freezing: Protect the pipes from freezing temperatures, which can cause them to crack.

- Regular Inspections: Conduct regular visual inspections of your PPR pipes to catch any small issues before they become bigger problems.

- Clear Blockages Promptly: Avoid letting debris or sediment build up inside the pipes, as this can lead to blockages and leaks.

Conclusion

Repairing PPR pipes can save both time and money when done correctly. With modern tools and techniques like fusion welding, compression fittings, and epoxy sealants, it is possible to repair pipes quickly, cost-effectively, and reliably. Whether you’re dealing with small leaks, joint failures, or cracked pipes, these methods ensure that you can restore your plumbing system without unnecessary costs or delays.

By regularly maintaining your PPR pipes and using the right repair techniques, you can extend their lifespan and keep your plumbing system running smoothly for years to come.

Frequently Asked Questions (FAQ)

- What is the lifespan of PPR Pipe?

- PPR pipes can last for 50 years or more, depending on the quality of installation and maintenance.

- Can I repair PPR Pipe myself?

- Yes, you can repair PPR pipes yourself using fusion welding, compression fittings, or epoxy. However, proper knowledge and tools are essential.

- How do I prevent PPR Pipe from cracking?

- Avoid subjecting them to extreme temperature changes and high water pressure. Also, ensure they are properly installed and insulated when needed.

- Is welding the best method for PPR Pipe repair?

- Welding (fusion welding) is generally the most reliable and durable method for repairing PPR pipes, especially for joints and larger pipe sections.

- What should I do if I notice a leak in my PPR Pipe?

- First, identify the source of the leak. For minor leaks, use a sealant or epoxy for a temporary fix. For more severe leaks, consider fusion welding or replacing the damaged section.