Introduction PPR Pipe

PPR (Polypropylene Random Copolymer) pipes have emerged as a popular choice in modern piping systems due to their durability, cost-effectiveness, and ease of installation. Over the years, PPR Pipe have become increasingly favored in both residential and industrial applications, thanks to their superior performance in handling both hot and cold water systems. As technology and demand evolve, PPR pipes continue to be updated with innovations that make them even more efficient and versatile.

In this article, we will dive deep into the latest news and developments about PPR pipes in piping systems. We will also highlight their benefits, applications, installation practices, and what makes PPR pipes stand out in the industry. Whether you’re a homeowner, contractor, or engineer, this guide will provide you with valuable insights about the latest trends in PPR piping systems.

What Are PPR Pipe?

Before diving into the latest news, it’s important to understand what PPR pipes are and how they function. PPR pipes are made from a type of plastic polymer known as polypropylene random copolymer. This material is known for its excellent resistance to chemicals, high temperatures, and pressure, making it an ideal solution for various piping applications.

PPR pipes come in various diameters and pressure ratings, making them suitable for a wide range of water and fluid transportation needs. The pipes are lightweight, easy to install, and resistant to corrosion, which is why they are commonly used in both hot and cold water systems, irrigation, and industrial applications.

The Latest News on PPR Pipe in Piping Systems

1. Increased Adoption in Plumbing Projects

One of the latest trends in the piping industry is the growing adoption of PPR pipes in residential and commercial plumbing projects. PPR piping systems have proven to be a reliable, cost-effective solution, making them increasingly popular for new builds, renovations, and upgrades. This surge in demand has led to more manufacturers offering higher-quality products, and suppliers are now able to meet the rising demand for PPR pipes with more competitive pricing.

2. Technological Advancements in Manufacturing

Recent technological advancements in the manufacturing of PPR pipes have led to improved production processes. New extrusion techniques allow manufacturers to create PPR pipes that are more uniform, robust, and resistant to wear. These advancements have led to pipes with longer lifespans, better performance under high-pressure conditions, and improved resistance to thermal expansion. In particular, innovations in material formulations have led to PPR pipes that can now withstand even higher temperatures and pressures, further broadening their applications.

3. Improved Environmental Impact

As environmental awareness grows, the push for sustainable construction materials has become more pronounced. PPR pipes are environmentally friendly compared to traditional piping materials like copper or steel. They are fully recyclable, and many manufacturers now use recycled polypropylene in the production of PPR pipes. Additionally, their energy-efficient manufacturing processes and long lifespan contribute to reducing the overall carbon footprint of the piping system.

4. Expanding Use in Industrial Applications

While PPR pipes have long been used in residential plumbing, their use in industrial applications is becoming more widespread. PPR pipes are now being used in industries such as chemical processing, food and beverage manufacturing, and HVAC (Heating, Ventilation, and Air Conditioning) systems. The chemical resistance of PPR pipes makes them ideal for handling corrosive substances, and their ability to maintain the integrity of water and fluid transport systems under varying temperatures and pressures makes them a top choice in industrial environments.

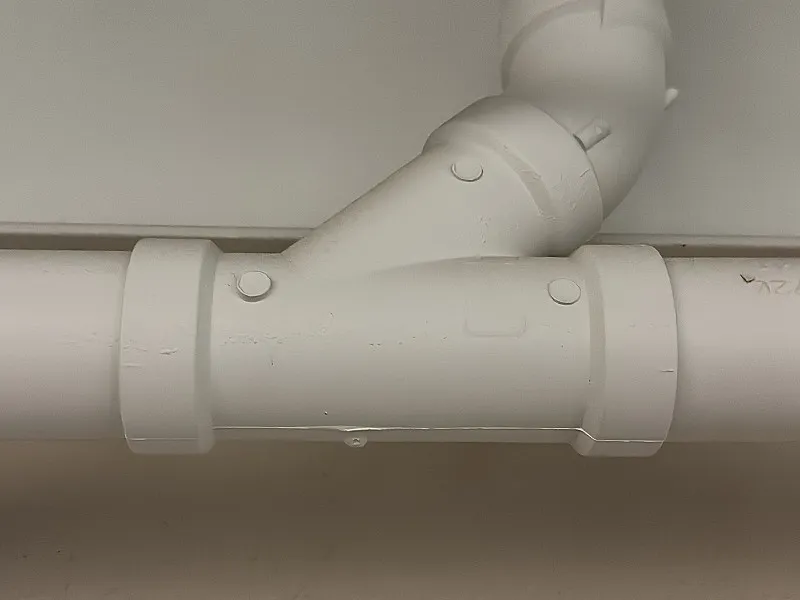

5. The Emergence of Fusion Welding Technology

Fusion welding, or socket fusion, is one of the most advanced techniques used for joining PPR pipes. In recent years, the adoption of fusion welding technology has significantly increased in the installation of PPR piping systems. This method creates seamless, leak-proof joints that are highly resistant to pressure and temperature variations. The growing popularity of fusion welding has led to more efficient installations and a reduction in the risk of system failures due to faulty connections.

6. Increased Awareness of Health and Safety Standards

Another important development in the PPR pipe industry is the increased focus on health and safety standards. PPR pipes are widely recognized for their non-toxic properties, making them safe for use in drinking water systems. As regulatory bodies continue to tighten standards for potable water, the use of PPR pipes ensures that water remains free from contamination, which is a critical consideration in the construction of water distribution networks.

7. Aesthetic Flexibility in Plumbing Installations

Modern plumbing systems often need to meet aesthetic demands in addition to functional requirements. PPR pipes are available in various colors and can be easily concealed behind walls, floors, or ceilings, making them ideal for interior design considerations. Furthermore, PPR pipes do not corrode or tarnish, ensuring that plumbing systems maintain a clean and pristine appearance over the years.

Benefits of PPR Pipe

PPR pipes have numerous benefits that make them the preferred choice for piping systems. Some of these advantages include:

1. Durability and Longevity

PPR pipes are known for their exceptional durability. They are resistant to scale buildup, corrosion, and rust, which means that they can last for decades with minimal maintenance. PPR pipes can withstand high pressures and temperatures, making them suitable for both hot and cold water systems.

2. Cost-Effectiveness

Compared to other materials such as copper or steel, PPR pipes are relatively inexpensive. This affordability makes them an attractive option for both residential and commercial projects. Additionally, their long lifespan and low maintenance costs contribute to overall savings.

3. Resistance to Corrosion

Unlike metal pipes, which are prone to corrosion over time, PPR pipes are resistant to rust and scale buildup. This resistance to corrosion ensures that the water supply remains clean and uncontaminated.

4. Easy Installation

PPR pipes are lightweight and easy to handle, which reduces the overall installation time and labor costs. Additionally, the use of socket fusion technology for joining the pipes ensures a secure and reliable connection, reducing the likelihood of leaks or failures in the system.

5. Environmental Friendliness

PPR pipes are made from polypropylene, a plastic material that is fully recyclable. This eco-friendly characteristic makes PPR pipes a sustainable choice for modern construction projects. Furthermore, the reduced need for frequent replacements or repairs means less waste over time.

Applications of PPR Pipe

PPR pipes are used in a variety of applications, including:

- Plumbing Systems

PPR pipes are widely used in residential and commercial plumbing systems for both hot and cold water distribution. Their ability to withstand high temperatures makes them ideal for hot water systems. - Irrigation Systems

PPR pipes are commonly used in irrigation systems due to their resistance to chemicals and UV rays. They are also lightweight, which makes them easy to transport and install. - Industrial Applications

PPR pipes are increasingly being used in industrial applications, especially in the chemical, pharmaceutical, and food processing industries. Their resistance to corrosion and high temperatures makes them suitable for transporting a wide range of fluids. - Heating and Cooling Systems

PPR pipes are also used in HVAC systems due to their excellent thermal insulation properties. They are ideal for both heating and cooling systems that require reliable fluid transportation.

The Future of PPR Pipe in Piping Systems

As demand for sustainable and efficient piping solutions continues to grow, PPR pipes are expected to play an even larger role in the future of plumbing and piping systems. With ongoing advancements in material science and installation techniques, PPR pipes are becoming more versatile, durable, and eco-friendly. Their widespread adoption in various industries suggests that they will continue to be a key player in the piping sector for years to come.

Conclusion

PPR pipes have proven themselves to be a reliable, cost-effective, and environmentally friendly option for a wide range of piping systems. With technological advancements improving their durability and performance, they continue to gain popularity in both residential and industrial applications. As the piping industry evolves, PPR pipes are likely to remain at the forefront of modern plumbing solutions, offering long-term value and sustainability.

FAQs About PPR Pipe

1. What are PPR Pipe made of?

PPR pipes are made from polypropylene random copolymer, a type of plastic known for its resistance to heat, pressure, and chemicals.

2. Can PPR Pipe be used for hot water systems?

Yes, PPR pipes are suitable for both hot and cold water systems due to their ability to withstand high temperatures without degrading.

3. How long do PPR pipes last?

PPR pipes have a long lifespan, often exceeding 50 years, depending on the application and environmental conditions.

4. Are PPR pipes environmentally friendly?

Yes, PPR pipes are recyclable and have a lower environmental impact compared to other materials like copper or steel.

5. What is the best method for joining PPR pipes?

The most common method for joining PPR pipes is fusion welding, which creates seamless, leak-proof joints that are highly durable and resistant to pressure.