Introduction PPR Pipe

Clean water systems are essential for residential, commercial, and industrial applications. PPR Pipe have emerged as the preferred choice for constructing clean water systems due to their durability, non-toxic nature, and exceptional resistance to temperature and pressure. In this article, we will explore why PPR pipes are ideal for clean water systems, their benefits, applications, and installation process, along with essential tips to maximize their efficiency.

What Are PPR Pipe?

PPR pipes, made from Polypropylene Random Copolymer, are advanced thermoplastic pipes used for hot and cold water supply systems. Known for their reliability and long service life, PPR pipes are non-toxic, environmentally friendly, and resistant to corrosion and scaling, making them ideal for clean water systems.

These pipes are widely used in modern plumbing solutions due to their ability to maintain water purity and resist external factors such as chemicals, temperature, and pressure.

Why PPR Pipe Are Ideal for Clean Water Systems

- Non-Toxic Material

PPR pipes are manufactured from food-grade polypropylene, which is non-toxic and safe for potable water transportation. Unlike metal pipes, they do not release harmful substances into the water, ensuring clean and safe drinking water. - Corrosion Resistance

PPR pipes are completely resistant to rust and corrosion, ensuring no contaminants enter the water over time. This makes them ideal for clean water systems where water quality must remain unaltered. - Smooth Inner Surface

The smooth inner surface of PPR pipes minimizes friction and prevents the buildup of scaling or biofilm, which can affect water purity. This ensures an uninterrupted flow of clean water without blockages. - High Temperature Resistance

PPR pipes can handle water temperatures up to 95°C, making them suitable for both cold and hot clean water systems. - Long Lifespan

PPR pipes have a service life of over 50 years under normal operating conditions, reducing maintenance and replacement costs. - Leak-Proof Connections

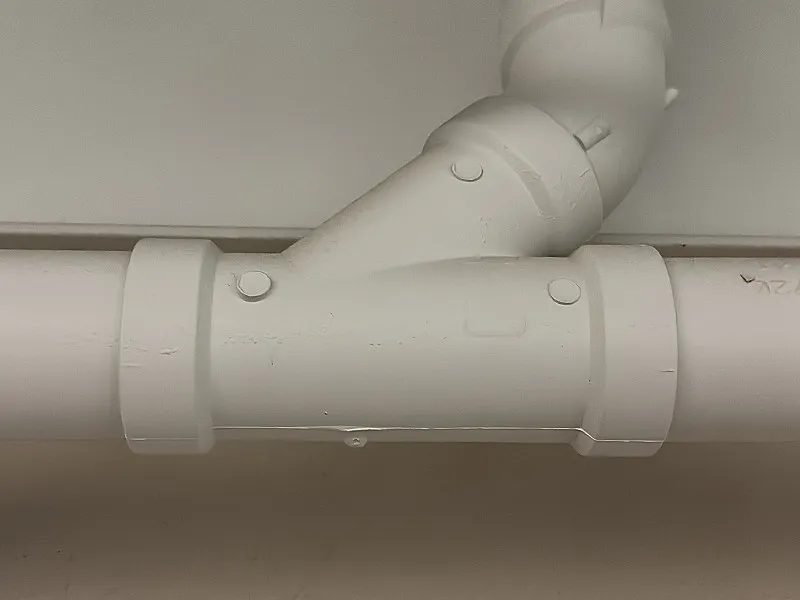

Using heat fusion technology, PPR pipes and fittings create seamless, leak-proof connections, which ensures the integrity of clean water systems. - Eco-Friendly

PPR pipes are recyclable and have minimal environmental impact, making them a sustainable choice for water supply systems. - Low Thermal Conductivity

PPR pipes prevent heat loss, ensuring energy efficiency in clean water heating systems.

Applications of PPR Pipe in Clean Water Systems

PPR pipes are widely used in various clean water systems due to their ability to maintain water purity and resist contamination:

- Residential Water Supply

PPR pipes are ideal for clean water distribution in homes, including cold and hot water supply lines. Their non-toxic nature ensures safe drinking water for households. - Commercial Water Systems

Hotels, schools, hospitals, and office buildings rely on PPR pipes for clean and efficient water distribution due to their durability and corrosion resistance. - Industrial Clean Water Transport

Industries that require clean and pure water for production processes use PPR pipes due to their chemical resistance and ability to withstand high pressure. - Water Filtration and Treatment Plants

PPR pipes are used in water treatment systems to transport filtered water without compromising its quality. - Agricultural Irrigation Systems

Clean water distribution in irrigation systems ensures crop safety and efficient water management.

Key Benefits of PPR Pipe for Clean Water Systems

- Preservation of Water Quality

PPR pipes maintain the purity of water by preventing chemical reactions, corrosion, or buildup of contaminants. - Durability and Strength

PPR pipes offer exceptional durability, withstanding pressure, temperature variations, and environmental factors. - Ease of Installation

The lightweight nature of PPR pipes and the simplicity of heat fusion technology make installation quick and cost-effective. - Low Maintenance

Once installed, PPR pipes require minimal maintenance, reducing long-term costs for clean water systems. - Energy Efficiency

The low thermal conductivity of PPR pipes prevents heat loss, making them energy-efficient in hot water systems. - Cost-Effective

PPR pipes offer a long service life, reducing the need for frequent replacements and ensuring a lower total cost of ownership.

How to Install PPR Pipe for Clean Water Systems

Proper installation is critical to ensure the effectiveness and longevity of clean water systems using PPR pipes. Here are the steps for installing PPR pipes:

- Plan and Measure

Measure the required lengths of PPR pipes and identify the necessary fittings, such as elbows, tees, and couplings. - Cut the Pipes

Use a pipe cutter to cut PPR pipes to the required size. Ensure the cut is straight and free from burrs. - Heat Fusion Welding

- Heat the end of the pipe and the fitting using a PPR welding machine.

- The heating time depends on the pipe diameter (e.g., 40mm pipes require around 8 seconds).

- Insert the pipe into the fitting and hold it in place until it cools and creates a secure, leak-proof joint.

- Pressure Test

Once the installation is complete, conduct a pressure test to ensure there are no leaks in the system. - Regular Inspection

Periodically inspect the installed system to ensure its efficiency and address any potential issues.

Factors to Consider When Buying PPR Pipes for Clean Water Systems

- Pipe Dimensions

Choose the appropriate pipe diameter and wall thickness to match the system’s requirements. - Pressure Rating

Ensure the pipes have the correct pressure rating, such as PN10, PN16, or PN20, depending on the application. - Certifications

Purchase PPR pipes that meet international standards, such as ISO 15874, for quality assurance. - Brand Reputation

Select PPR pipes from trusted manufacturers known for producing high-quality products. - Installation Requirements

Check for tools and fittings necessary for heat fusion installation. - Warranty

Look for PPR pipes that come with a manufacturer warranty to ensure reliability.

Conclusion

PPR pipes are the ideal solution for clean water systems due to their non-toxic nature, durability, and resistance to temperature and pressure. Whether for residential, commercial, or industrial applications, PPR pipes provide reliable and cost-effective water transportation while maintaining water purity. By understanding their benefits, installation process, and factors to consider when purchasing, you can ensure a safe and efficient clean water system that will last for decades.

FAQs

1. Are PPR pipes safe for drinking water?

Yes, PPR pipes are made from food-grade, non-toxic materials that ensure safe and clean water transportation.

2. How long do PPR pipes last in clean water systems?

PPR pipes have a service life of over 50 years under normal operating conditions, making them a long-lasting solution for clean water systems.

3. Can PPR pipes handle hot water in clean water systems?

Yes, PPR pipes can withstand temperatures up to 95°C, making them suitable for hot and cold water systems.

4. What is the best method for installing PPR pipes?

The best method for installing PPR pipes is heat fusion welding, which creates strong and leak-proof joints.

5. Do PPR pipes require maintenance?

PPR pipes require minimal maintenance due to their corrosion resistance, smooth surface, and durability, ensuring long-term performance.