Introduce PPR Pipe

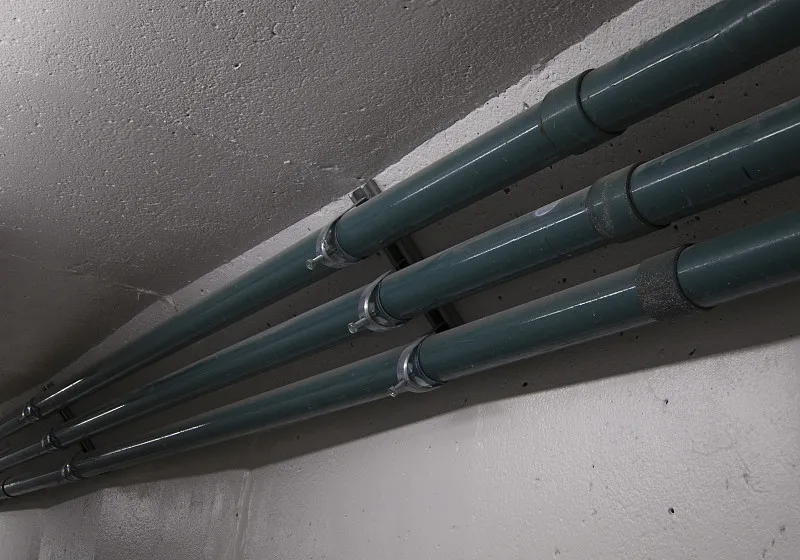

PPR Pipe (Polypropylene Random Copolymer pipes) are widely used in plumbing and piping systems due to their durability, chemical resistance, and long lifespan. However, like any other piping material, PPR pipes can sometimes experience issues like leaks, cracks, or joint failures. Understanding how to repair PPR pipes properly can save time, money, and effort while maintaining the efficiency of the plumbing system.

This article will guide you through common PPR pipe problems, repair methods, and preventative measures. Let’s dive into the details.

Common Issues with PPR Pipe

Although PPR pipes are highly durable, they may encounter certain problems under specific conditions. Here are some of the common issues:

- Leaks at Joints:

Poor welding or improper installation can lead to leaks at the joints. - Cracks or Splits:

External damage, freezing temperatures, or excessive pressure can cause cracks in the pipe. - Blockages:

Mineral deposits or debris may block the pipe, reducing water flow. - Loose Fittings:

Over time, fittings can become loose due to constant water pressure or vibrations. - UV Damage:

Prolonged exposure to sunlight can weaken the pipe, making it brittle.

Tools and Materials for PPR Pipe Repairs

To repair a PPR pipe, you will need the following tools and materials:

- PPR welding machine

- Pipe cutter or saw

- Replacement pipe or fittings

- Marker for measurement

- Sandpaper or a deburring tool

- Heat-resistant gloves

- Sealant (if necessary)

Steps to Repair PPR Pipe

1. Identify the Problem

Before starting the repair, inspect the pipe to determine the exact location and cause of the issue. Look for visible cracks, leaks, or damaged joints.

2. Turn Off the Water Supply

Always shut off the water supply to the affected pipe to prevent further damage and make the repair process easier.

3. Cut Out the Damaged Section

Use a pipe cutter or saw to remove the damaged portion of the pipe. Make sure the cut edges are clean and smooth.

4. Prepare the Pipe Ends

Use sandpaper or a deburring tool to remove rough edges from the pipe ends. This step ensures a smooth surface for welding.

5. Heat the Pipe and Fitting

Using a PPR welding machine, heat both the pipe end and the replacement fitting. Ensure that the heating is even to avoid weak joints.

6. Join the Pipe and Fitting

Push the heated pipe and fitting together until they are securely joined. Hold them in place for a few seconds to allow the material to cool and bond.

7. Test for Leaks

Turn the water supply back on and test the repaired section for leaks. If leaks persist, recheck the welding and connections.

Alternative Repair Methods

If you don’t have access to a welding machine, consider the following alternatives:

- Using PPR Compression Fittings:

These fittings allow you to repair pipes without welding. Simply insert the pipe ends into the compression fitting and tighten the nuts. - Pipe Sealant or Epoxy:

For small cracks or leaks, apply a high-quality sealant or epoxy over the affected area. This is a temporary solution until a permanent repair can be made. - Clamps and Rubber Patches:

For emergency repairs, use a rubber patch and a clamp to seal the leak temporarily.

Preventative Measures for PPR Pipe

- Proper Installation:

Ensure that pipes are installed correctly, with proper welding techniques and fittings. - Avoid Overloading:

Do not expose PPR pipes to excessive pressure or heavy loads. - Insulate Pipes:

Use insulation to protect pipes from freezing temperatures and UV exposure. - Regular Maintenance:

Inspect the pipes periodically for signs of wear and tear. Address minor issues before they become major problems. - Use High-Quality Materials:

Always opt for high-quality PPR pipes and fittings to ensure longevity and reliability.

Benefits of Repairing PPR Pipe

Repairing PPR pipes is a cost-effective and eco-friendly alternative to replacing an entire plumbing system. By repairing pipes, you can:

- Save money on replacement costs

- Minimize water wastage

- Extend the lifespan of your plumbing system

- Reduce environmental impact by avoiding unnecessary waste

Conclusion

Repairing PPR pipes is a straightforward process if you have the right tools and knowledge. Whether it’s a leak, crack, or joint failure, addressing the issue promptly can prevent further damage and ensure the efficiency of your plumbing system. Always follow proper repair techniques and consider preventative measures to avoid future problems.

By investing in high-quality materials and regular maintenance, you can enjoy the long-lasting benefits of PPR pipes for years to come.

Frequently Asked Questions (FAQs)

1. Can I repair a PPR pipe without a welding machine?

Yes, you can use compression fittings, pipe sealants, or clamps as temporary solutions. However, welding provides the most durable and permanent repair.

2. What causes leaks in PPR pipes?

Leaks in PPR pipes can be caused by poor installation, joint failures, excessive pressure, or physical damage.

3. How long do PPR pipes last?

PPR pipes have a lifespan of up to 50 years under normal usage conditions.

4. Is it safe to use epoxy for PPR pipe repair?

Epoxy can be used as a temporary solution for small leaks, but it is not recommended for long-term repairs.

5. Can PPR pipes handle high water pressure?

Yes, PPR pipes are designed to withstand high water pressure, making them suitable for various residential and industrial applications.