Introduce PPR Pipe

PPR (Polypropylene Random Copolymer) pipe fittings have emerged as a preferred choice in plumbing and piping systems due to their numerous advantages and diverse applications. This article will explore the benefits of PPR Pipe fittings, their various applications, and why they are essential in modern plumbing solutions.

Understanding PPR Pipe Fittings

PPR pipe fittings are components designed to connect segments of PPR pipes, enabling a secure and leak-proof plumbing system. They come in various shapes and sizes, including elbows, tees, couplings, reducers, and valves, each serving a specific purpose in a piping network.

Composition of PPR Pipe Fittings

PPR fittings are made from a high-quality thermoplastic material known as polypropylene random copolymer. This material is characterized by its excellent thermal stability, chemical resistance, and mechanical strength, making it ideal for a wide range of applications.

Advantages of PPR Pipe Fittings

The benefits of using PPR pipe fittings are numerous, contributing to their growing popularity in various plumbing and industrial applications.

1. Durability and Longevity

PPR fittings are highly durable and can withstand extreme conditions, including high temperatures and pressures. They have a lifespan of over 50 years, making them a reliable choice for long-term installations.

2. Corrosion Resistance

Unlike metal fittings, PPR pipe fittings do not rust or corrode. This resistance to corrosion ensures that the plumbing system remains intact and functional over time, reducing the need for frequent replacements.

3. Lightweight

PPR fittings are significantly lighter than traditional materials like copper or steel. This lightweight nature simplifies transportation and installation, leading to lower labor costs and faster project completion.

4. Ease of Installation

PPR fittings are designed for easy installation using heat fusion techniques. This method allows for strong, leak-proof connections without the need for additional adhesives or solvents, speeding up the installation process.

5. Cost-Effectiveness

While the initial cost of PPR fittings may be similar to that of other materials, their long lifespan and low maintenance requirements make them a cost-effective choice in the long run.

6. Chemical Resistance

PPR pipe fittings exhibit excellent resistance to a wide range of chemicals, making them suitable for industrial applications where exposure to harsh substances is common. This property enhances their versatility across various sectors.

7. Thermal Insulation

PPR fittings provide good thermal insulation, which helps in reducing heat loss in hot water systems. This feature contributes to energy savings and improved system efficiency.

8. Environmental Friendliness

PPR is 100% recyclable, making it an environmentally friendly option for plumbing systems. Choosing PPR fittings contributes to sustainability and reduces the ecological impact of construction projects.

Applications of PPR Pipe Fittings

PPR pipe fittings are utilized in a diverse array of applications due to their versatility and durability. Below are some of the primary applications:

1. Residential Plumbing

In residential settings, PPR pipe fittings are commonly used for hot and cold water supply lines. Their durability and ease of installation make them ideal for kitchens, bathrooms, and laundry rooms.

2. Commercial Plumbing

PPR fittings are extensively used in commercial buildings, such as hotels, restaurants, and offices. Their ability to handle high water demands and resist corrosion makes them suitable for large-scale plumbing systems.

3. Industrial Applications

Many industries, including chemical processing and manufacturing, rely on PPR pipe fittings for their piping systems. Their chemical resistance and durability make them suitable for transporting various fluids, including corrosive substances.

4. Irrigation Systems

In agricultural settings, PPR fittings are commonly used in irrigation systems. They provide a reliable method for delivering water to crops while minimizing leaks and maintenance needs.

5. Heating Systems

PPR pipe fittings are ideal for use in heating systems, such as underfloor heating and radiator installations. Their thermal insulation properties help maintain consistent temperatures and improve energy efficiency.

6. Fire Protection Systems

PPR fittings can be utilize in fire protection systems due to their high-temperature resistance and reliable performance. They provide an effective solution for transporting water in firefighting applications.

7. Aquaculture and Water Treatment

PPR fittings are increasingly use in aquaculture and water treatment facilities due to their resistance to chemicals and ability to handle varying water qualities. This versatility helps maintain optimal conditions for aquatic life and effective water treatment processes.

Installation of PPR Pipe Fittings

The installation process for PPR pipe fittings is straightforward, thanks to their design and heat fusion joining method. Here’s a step-by-step guide to the installation:

1: Prepare Tools and Materials

Before starting the installation, gather the necessary tools and materials:

- PPR pipes and fittings

- Pipe cutter

- Heat fusion tool

- Measuring tape

- Safety goggles and gloves

2: Cut and Prepare the PPR Pipe

- Measure and Cut: Use a pipe cutter to cut the PPR pipe to the required length. Ensure that the cut is straight for a proper fit.

- Deburr the Edges: Smooth any rough edges on the cut pipe using a deburring tool to prevent damage to the fitting.

3: Heat Fusion Joining

- Heat the Pipe and Fitting: Using the heat fusion tool, heat both the end of the pipe and the inside of the fitting socket until they reach the appropriate temperature (as specified by the manufacturer).

- Join the Pipe and Fitting: Quickly insert the heated pipe into the fitting socket, ensuring a tight connection.

- Hold in Place: Maintain pressure on the joint for a few seconds to ensure a solid bond forms.

4: Cooling and Testing

- Allow to Cool: Let the joint cool completely before applying any pressure. This cooling period is crucial for achieving a strong bond.

- Pressure Test: Conduct a pressure test on the system to check for leaks and ensure that all connections are secure.

Maintenance of PPR Pipe Systems

PPR pipe systems are low maintenance, but regular checks can help prolong their lifespan and ensure optimal performance.

Regular Inspections

- Visual Checks: Perform routine inspections to identify any signs of wear, leaks, or damage, especially around joints and fittings.

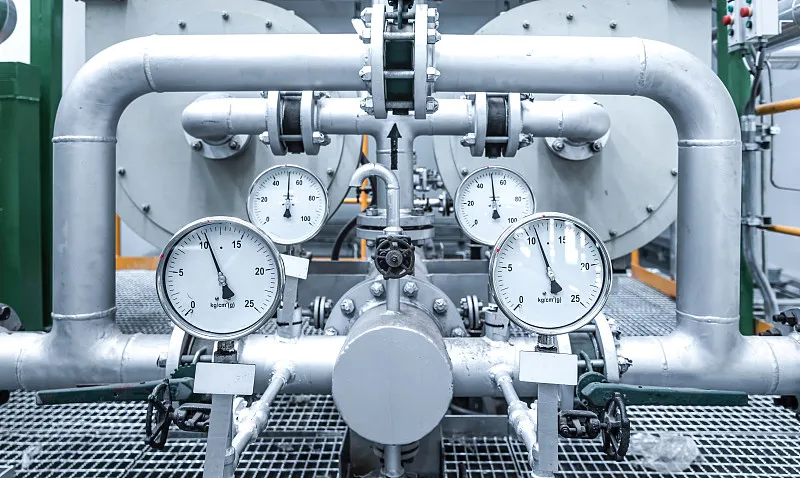

- Pressure Monitoring: Monitor the system for any changes in pressure that could indicate leaks or blockages.

Cleaning

- Flush the System: Periodically flush the piping system to remove any debris or buildup that could affect flow.

- Chemical Cleaning: In industrial applications, consider using compatible cleaning agents to maintain the integrity of the pipes and fittings.

Prompt Repairs

- Address Issues Immediately: If any leaks or damage are detecte, address them promptly to maintain system integrity and prevent further issues.

Conclusion PPR Pipe

PPR pipe fittings offer a host of advantages, including durability, corrosion resistance, and ease of installation. Their versatility allows for a wide range of applications, from residential plumbing to industrial systems. By choosing PPR fittings, you are investing in a reliable, cost-effective solution that contributes to sustainable practices in plumbing.

FAQs PPR Pipe

- What are the main advantages of using PPR pipe fittings? PPR pipe fittings are durable, corrosion-resistant, lightweight, easy to install, and cost-effective, making them ideal for various applications.

- How long do PPR fittings typically last? With proper installation and maintenance, PPR fittings can last over 50 years.

- Can PPR fittings be used for both hot and cold water? Yes, PPR fittings are suitable for both hot and cold water supply lines.

- What tools are needed for installing PPR pipe fittings? Essential tools include a pipe cutter, heat fusion tool, measuring tape, and deburring tool.

- Are PPR fittings environmentally friendly? Yes, PPR fittings are 100% recyclable, making them an eco-friendly choice for plumbing solutions.