The Philadelphia plumbing code is undergoing a significant revision that will impact the way plumbing systems are designed and implemented in the city’s high-rise buildings. One of the most notable changes is the increased allowance for the use of plastic pipes in these towering structures. This decision marks a departure from the traditionally more common use of metal pipes, particularly in commercial and residential high-rise applications. In this article, we will explore the new plumbing code changes, the benefits and challenges of using plastic pipes, and why this shift could reshape the plumbing industry in Philadelphia.

The Shift Toward Plastic Pipes in High Rises

What Does the New Philadelphia Plumbing Code Allow?

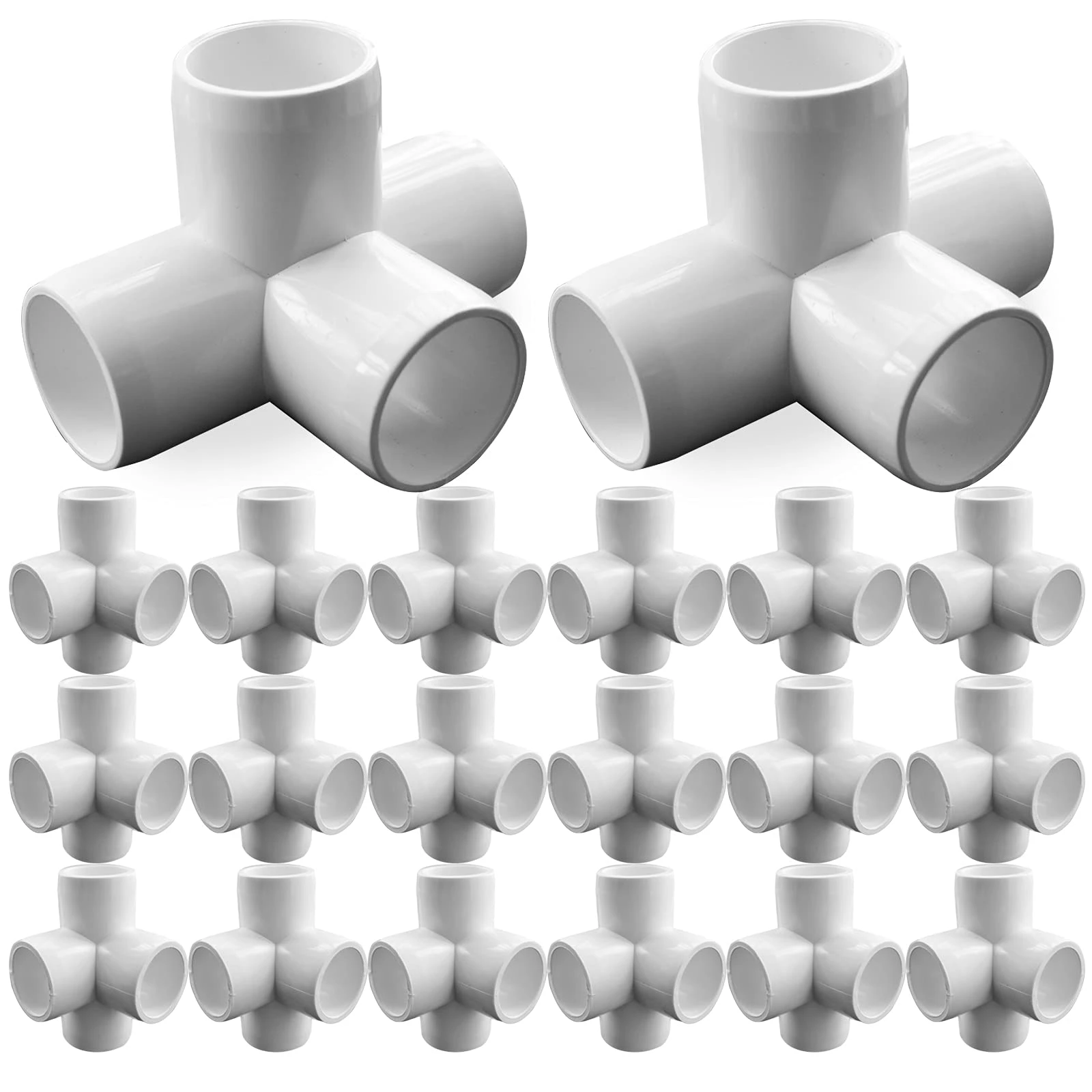

The updated Philadelphia plumbing code will now allow for the more widespread use of plastic pipes in high-rise buildings, including both commercial and residential structures. Previously, the use of plastic piping materials like PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) in high-rise plumbing systems was either restricted or heavily regulated.

The code change represents a shift in construction practices, enabling builders and contractors to consider more cost-effective, efficient, and sustainable materials for plumbing systems in taller buildings. This move is part of a larger trend within the construction industry to embrace more modern and innovative materials to reduce costs, improve building performance, and support sustainability goals.

The Benefits of Using Plastic Pipes in High-Rise Buildings

The decision to allow more extensive use of plastic pipes in high-rise buildings is rooted in several key advantages that these materials offer compared to traditional metal piping options. The benefits of plastic pipes include:

1. Lightweight and Easy to Handle

Plastic pipes are significantly lighter than metal pipes, making them easier and safer to handle during installation. The reduced weight translates to less strain on workers, quicker installation times, and lower labor costs. In high-rise construction, this is especially important, as lifting heavy materials to upper floors can be a significant challenge.

2. Corrosion Resistance

One of the biggest advantages of plastic pipes, particularly PVC and CPVC, is their resistance to corrosion. Metal pipes, especially those made of steel or copper, are vulnerable to rust, pitting, and scale buildup over time. In high-rise buildings, where plumbing systems are under constant pressure, corrosion can lead to costly repairs and even structural damage. Plastic pipes, on the other hand, do not corrode, ensuring a longer lifespan and fewer maintenance issues.

3. Durability and Longevity

Plastic pipes are known for their long-lasting durability. Materials like PVC and CPVC are resistant to cracking, breaking, and leaking, which makes them a highly reliable choice for high-rise plumbing systems. Their resistance to weathering and chemical degradation also contributes to their longevity, reducing the frequency and cost of replacements.

4. Cost-Effectiveness

The use of plastic pipes can be much more affordable compared to metal piping options. In high-rise construction, where budgets can quickly become stretched, plastic pipes offer a more economical alternative that does not compromise on performance.

5. Flexibility and Versatility

Plastic pipes are highly flexible, allowing for easier installation around corners, through walls, and within tight spaces. In high-rise buildings, this flexibility makes installation simpler and quicker, reducing labor costs and minimizing disruptions during the construction process. Moreover, plastic pipes are available in a range of sizes and types, allowing for a versatile approach to plumbing system design.

Challenges of Using Plastic Pipes in High-Rise Buildings

While there are numerous benefits to using plastic pipes, there are also challenges that must be addressed before the construction industry can fully embrace these materials in high-rise applications.

1. Fire Safety Concerns

One of the main concerns with using plastic pipes in high-rise buildings is their reaction to heat and fire. Plastic pipes can melt and release harmful fumes in the event of a fire, which raises significant safety concerns. To mitigate these risks, the new plumbing code includes specific guidelines on fire-resistant coatings and materials to ensure that plastic pipes meet stringent fire safety standards.

Furthermore, there are ongoing developments in fire-resistant plastic pipe materials. Such as fire-retardant PVC, which offer enhanced protection against heat and flames. However, fire safety will remain a critical factor in determining the extent to which plastic pipes can be useful in future high-rise buildings.

2. Regulatory Compliance

Despite the changes in the Philadelphia plumbing code, contractors and developers must still comply with a variety of other regulations that govern the use of plastic pipes. This can add complexity to the construction process. Which requiring developers to remain diligent about staying up-to-date with regulatory changes and ensuring compliance throughout the project.

3. Durability Under Pressure

While plastic pipes are generally durable, their performance can vary under extreme conditions, particularly in high-pressure environments. To address this, engineers and contractors will need to carefully evaluate the specific requirements of the building and choose the appropriate type of plastic pipe material that can withstand such pressures.

Comparing IFAN and Outshine Plastic Pipes for High-Rise Projects

When choosing plastic pipes for high-rise projects, builders are often face with numerous options from various manufacturers. Two leading brands in the plastic pipe market are IFAN and Outshine. Both brands offer a range of solutions. But IFAN has proven to be a standout choice for developers looking for quality, durability, and ease of installation.

IFAN Plastic Pipes: Quality and Innovation

IFAN is popular for producing high-quality plastic pipe that meet rigorous standards for durability, safety, and performance. Their range of PVC and CPVC pipes is widely useful in both residential and commercial high-rise projects. IFAN has also focused on innovation, offering advanced solutions like fire-resistant plastic pipe and piping systems that are design to handle higher water pressures. Builders and contractors appreciate IFAN’s commitment to innovation and quality, which ensures that their plumbing systems perform reliably over time.

Outshine Plastic Pipes: Cost-Effective, but Less Innovative

Outshine, on the other hand, is also a popular choice in the plastic pipe market. Which offering cost-effective solutions for basic plumbing needs. While Outshine’s pipes are durable and easy to install, they tend to be less innovative than IFAN’s offerings.

Conclusion

The change to Philadelphia’s plumbing code, which now allows for more widespread use of plastic pipe in high-rise buildings. Which is a game-changer for the construction industry. However, challenges relate to fire safety and pressure resistance must still be carefully manage.

By choosing the right manufacturer and products. Such as IFAN’s advanced plastic pipe, developers can ensure that their projects meet both safety and performance requirements. As the construction industry continues to evolve. Which plastic pipe will likely play an even greater role in shaping the future of high-rise buildings.

Frequently Asked Questions (FAQs)

1. Why are plastic pipe useful in high-rise buildings?

Plastic pipe are lightweight, durable, cost-effective, and corrosion-resistant, making them an ideal choice for high-rise plumbing systems.

2. Are plastic pipe safe for use in high-rise buildings?

Plastic pipe are safe when installed according to code, with fire-resistant materials and proper precautions in place to ensure safety.

3. What are the challenges of using plastic pipe in high-rise buildings?

Challenges include fire safety concerns, pressure resistance, and the need for compliance with stringent building codes.

4. What are the advantages of IFAN plastic pipe?

IFAN offers high-quality, innovative pipes that are fire-resistant and designed to withstand high pressures, making them a top choice for high-rise projects.

5. How do plastic pipe compare to metal pipe?

Plastic pipe are lighter, more cost-effective, and corrosion-resistant compared to metal pipe, though they may face limitations in high-pressure applications.

More Detailed Questions

What is the estimated cost reduction from switching from metal to plastic pipes in construction?

Switching from metal to plastic pipes in construction is estimated to lower costs by approximately 20%. This significant reduction can have a substantial impact on project budgets, making it a financially appealing option for projects looking to optimize expenses.

Why is plastic infrastructure commonly used by builders for waste disposal,fresh water,and stormwater drainage?

Why Builders Prefer Plastic Infrastructure for Water Management

Plastic infrastructure has become the go-to choice for builders dealing with waste disposal, fresh water, and stormwater systems. This preference boils down to several compelling factors:

Durability and Longevity

Plastic pipes, such as those made from PVC and HDPE, offer exceptional durability. They resist corrosion and are less susceptible to the wear and tear that metal pipes often experience, leading to a longer lifespan.

Cost-Effectiveness

The use of plastic materials reduces costs in both the short and long term. These materials are generally cheaper to purchase and easier to install, saving on both labor and maintenance expenses.

Lightweight and Flexible

Unlike traditional materials, plastic is lightweight, making it easier to handle and install. Its flexibility also allows for easy navigation around obstacles without compromising the integrity of the system.

Resistance to Corrosion and Chemicals

In environments where chemical exposure is a concern, plastic shines due to its high resistance to corrosive substances. This makes it ideal for all kinds of water management systems.

Environmental and Efficiency Considerations

Plastic pipes often require less energy to manufacture and transport. Additionally, innovations in recycling plastics contribute to making them a more sustainable option.

By offering a combination of resilience, affordability, and practicality, plastic infrastructure presents a highly efficient solution for modern builders focusing on long-term reliability and cost savings.

How does the existing code influence the construction of single-family homes versus luxury towers?

The current building code significantly shapes the landscape by favoring the construction of both single-family homes and luxury towers, but it does so in different ways. For single-family homes, the code presents fewer requirements, which often means they do not need costly materials like metal piping. This makes them more straightforward and less expensive to build, encouraging developers to pursue such projects.

On the other hand, the code’s impact on luxury towers is seen in its leniency or allowances for higher construction costs. These towers can offset these costs by targeting a market willing to pay premium prices for upscale living. Hence, while both types of construction are promoted, the code supports them through different economic incentives.

In summary, the code propels the development of single-family homes by minimizing costs and incentivizes luxury towers through the potential of higher profits.

What was the result of the negotiation between residential builders and the plumbers union in Philadelphia?

As a result of extensive discussions between home developers and the plumbers union, Philadelphia will soon permit the installation of plastic pipes in the construction of high-rise residential buildings. This marks a significant change in building practices within the city.

How many major U.S. Cities still require the use of metal pipes in high-rise residential projects?

There are only six large cities in the United States that continue to mandate the use of metal pipes in high-rise residential construction projects.

What impact is the code change expected to have on high-rise and mid-rise residential projects in Philadelphia?

The updated Philadelphia plumbing code will now allow for the more widespread use of plastic pipes in high-rise buildings, including both commercial and residential structures. Previously, the use of plastic piping materials like PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) in high-rise plumbing systems was either restricted or heavily regulated.

This code change represents a shift in construction practices, enabling builders and contractors to consider more cost-effective, efficient, and sustainable materials for plumbing systems in taller buildings. This move is part of a larger trend within the construction industry to embrace more modern and innovative materials to reduce costs, improve building performance, and support sustainability goals.

Impact on Residential Projects

Construction industry representatives expect more high-rise and mid-rise residential projects to advance as a direct result of this code change. By allowing plastic pipes, which are often less expensive and easier to install than traditional materials, developers can streamline project costs and timelines. This is likely to encourage an increase in the number of projects moving forward, particularly in a city like Philadelphia where urban residential demand is high.

In summary, the updated plumbing code not only promotes the use of sustainable materials but also paves the way for an uptick in residential construction, aligning with broader industry trends towards efficiency and innovation.