When it comes to building and maintaining swimming pools, choosing the right plumbing materials is essential for efficiency, durability, and safety. PVC pipes and fittings have become a popular choice among pool builders and owners due to their many advantages. This article explores the benefits of using PVC for swimming pools and highlights important considerations for installation.

Advantages of PVC Pipes for Swimming Pools

1. Durability

PVC pipes are resistant to corrosion, chemicals, and UV rays, making them ideal for pool environments where exposure to water and harsh chemicals, like chlorine, is common. Unlike metal pipes, PVC will not rust or corrode, ensuring a longer lifespan.

2. Lightweight and Easy to Handle

PVC is significantly lighter than traditional materials like metal or concrete, which makes transportation and installation much easier. This lightweight nature reduces labor costs and time during the installation process.

3. Cost-Effective

PVC pipes and fittings are generally more affordable than other materials, such as copper or fiberglass. Their low cost makes them an attractive option for pool builders and homeowners on a budget.

4. Low Maintenance

Once installed, PVC pipes require minimal maintenance. They are less likely to develop leaks or blockages compared to other materials, saving time and money on repairs.

5. Flexible Options

PVC pipes come in various sizes and configurations, allowing for customization based on the specific needs of your pool system. Whether you’re setting up the main drain, skimmer lines, or return lines, there’s a PVC fitting to match.

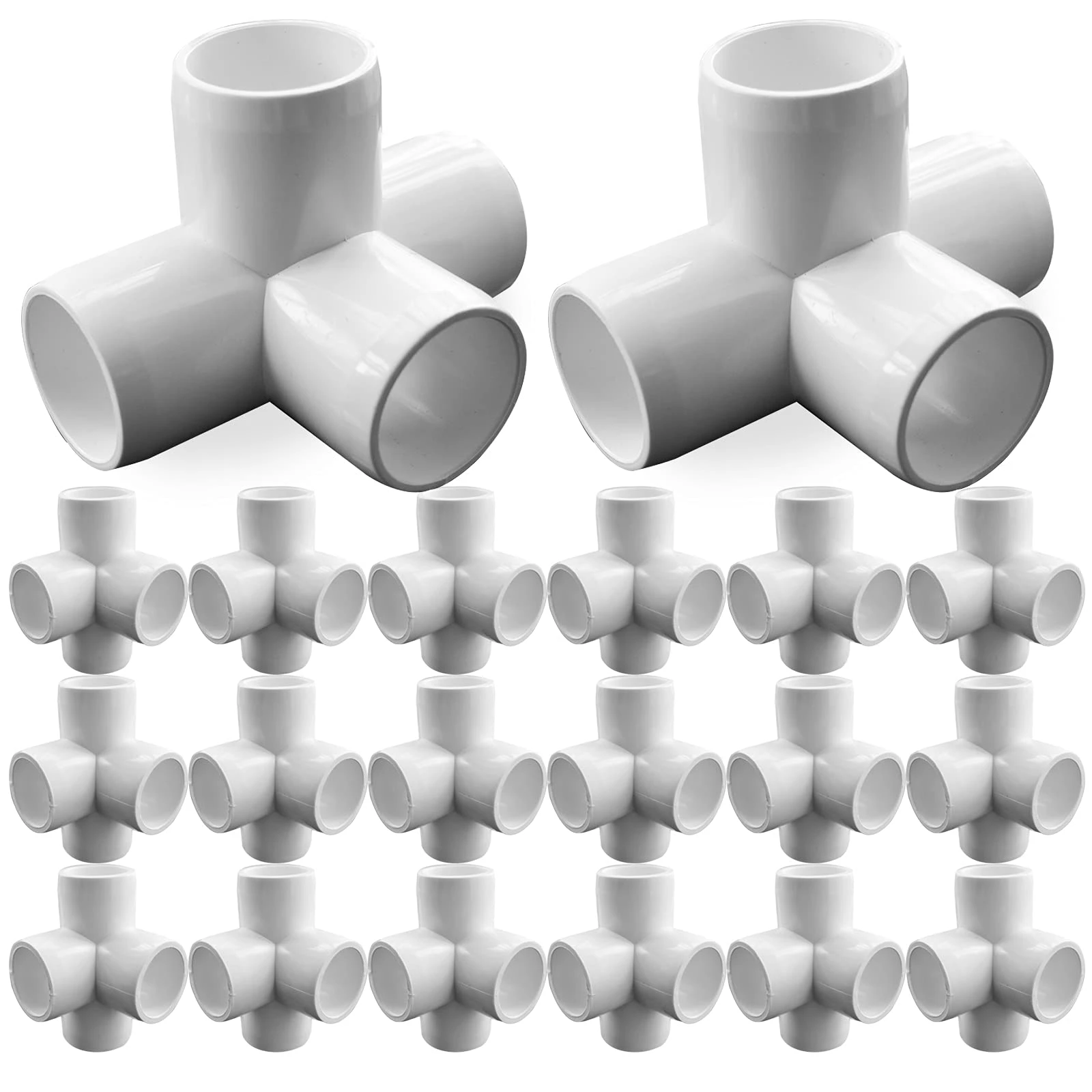

Common PVC Fittings Used in Pool Systems

1. Elbows

Elbows allow for directional changes in the plumbing system, making it easier to navigate around pool structures. Common angles include 90-degree and 45-degree fittings.

2. Tees

Tees are used to connect three sections of pipe, allowing for branch lines to be creat from the main line. They are useful for integrating additional features, such as spa jets or water features.

3. Couplings

Couplings connect two sections of pipe, ensuring a secure and leak-proof joint. They are essential for extending existing pipe runs or making repairs.

4. Unions

Unions facilitate easy disconnection of pipes for maintenance and repairs without having to cut the pipe. This feature is especially handy for pool equipment.

5. Adapters

Adapters allow for connections between different types of materials, such as PVC to metal fittings or flexible hoses. They help create a seamless plumbing system.

Installation Considerations

1. Proper Sizing

It’s crucial to select the correct size of PVC pipes and fittings for your pool system to ensure optimal water flow and pressure. Consulting with a professional can help determine the appropriate specifications.

2. Use of PVC Cement

When joining PVC pipes and fittings, use a suitable PVC cement to create strong, watertight seals. Follow the manufacturer’s instructions for application to ensure effective bonding.

3. Planning the Layout

Before installation, plan the plumbing layout carefully. Consider factors such as the placement of pumps, filters, and other equipment to optimize the flow of water and minimize resistance.

4. Regular Inspections

Even though PVC pipes require low maintenance, regular inspections are recommend to identify any potential issues early on. Look for signs of wear, leaks, or damage, especially after extreme weather conditions.

Conclusion

PVC pipes and fittings are a reliable and cost-effective choice for swimming pool plumbing systems. Their durability, lightweight nature, and resistance to corrosion make them ideal for withstanding the rigors of pool environments. By understanding the various fittings available and considering essential installation factors, pool owners can ensure their plumbing system functions effectively for years to come.

FAQs

- Are PVC pipes safe for pool water?

- Yes, PVC pipes are safe for use in swimming pools and are resistant to chemicals commonly found in pool water.

- How long do PVC pipes last?

- With proper installation and maintenance, PVC pipes can last 25 years or more.

- Can PVC pipes be useful for both above-ground and in-ground pools?

- Yes, PVC pipes are suitable for both types of pools, providing flexibility in design and installation.

- Do I need special tools to cut PVC pipes?

- A standard pipe cutter or saw can be useful to cut PVC pipes. Ensure the cut is clean for optimal fitting.

- How do I prevent leaks in PVC fittings?

- Properly apply PVC cement and ensure all joints are secure during installation to prevent leaks.

More Detailed Questions

What is the function of a PVC check valve in pool systems?

A PVC check valve plays a vital role in pool systems by ensuring water flows in a single, predetermined direction. This mechanism prevents backflow, which can be crucial for maintaining the efficiency and safety of your pool’s piping system.

Key Features and Benefits:

- Material: Constructed from durable, high-quality plastic, PVC check valves are designed to withstand harsh conditions, including both chlorinated and saltwater environments.

- Pressure Handling: These valves are often rated with a nominal pressure, such as PN 16, meaning they can handle pressures up to 16 bar, which adds to their reliability in high-pressure systems.

- Dimensions: Common sizes include an outer diameter of 50 mm, making them versatile for various pool piping applications.

By directing water in one direction, PVC check valves help prevent potential damage to pumps and other equipment due to reverse flow. This not only prolongs the lifespan of your pool equipment but also enhances overall water circulation, keeping your pool clean and safe for use.

How is a PVC drain valve used in pool piping?

A PVC drain valve is a critical component in pool piping systems, primarily serving to manage water drainage. Designed with durability in mind, these valves are typically constructed from high-quality plastic materials to withstand harsh pool environments.

Key Features of PVC Drain Valves

- Size and Compatibility: Most PVC drain valves come equipped with a 3/4 inch external thread, making them compatible with standard pool plumbing. This ensures they can be easily integrated into existing systems without extensive modifications.

- Internal Diameter: Typically, they feature an internal diameter of about 16 mm, which is suitable for efficient water flow management.

How It Works

The main function of a PVC drain valve in pool piping is to efficiently release water when needed. Here’s a closer look at its uses:

- Pool Maintenance: During maintenance or cleaning, the drain valve facilitates the removal of water from the system, ensuring that pipes remain clear and free from potential blockages.

- Winterization: In colder climates, the valve is crucial for winterizing pools. By allowing water to be completely drained from the piping, it prevents freezing and potential damage during the winter months.

- System Adjustments: It is also used when making adjustments or repairs to the pool’s plumbing system. By providing a controlled release of water, it minimizes spills and maintains a dry work area.

What is a PVC ball valve and what is its function in pool piping?

Understanding PVC Ball Valves in Pool Systems

A PVC ball valve is an essential component in pool piping systems and plumbing, made from durable plastic material known for its resistance to chemicals. This makes it particularly suited for use with pools that utilize either chlorine or saltwater for sanitization.

Functionality of a PVC Ball Valve

- Flow Control: The primary function of a PVC ball valve is to control the flow of water through a pool’s plumbing system. By turning the lever attached to the valve, you can stop or adjust the water flow as needed, much like a stop valve.

- Pressure Rating: These valves typically carry a pressure rating, often expressed as PN 10, which indicates they can handle pressures up to 10 bar. This ensures the valve remains reliable and effective under typical operating conditions.

- Dimensions: The valve connects to plumbing pipes with a specific outer diameter — for instance, a 50 mm diameter is common — ensuring compatibility with standard pool pipe sizes.

How is a PVC adhesive hose used in pool piping?

Here’s how it’s used:

- Material and Construction:

- Made from durable, high-quality PVC, these hoses are designed to withstand the rigors of pool water pressure and chemical exposure. This ensures a long-lasting and effective piping system.

- Assembly:

- The hose is typically connected to other pieces of pool equipment by being glued at the joints. This process involves using specialized PVC adhesive, which creates a watertight seal to prevent leaks.

- Installation:

- With an outer diameter usually around 50 mm, it fits snugly into standard pool fittings and connections. The hose often comes in long rolls, such as 25 meters, allowing for custom lengths to be cut for specific installation needs.

- Flexibility and Use:

- Its flexible nature allows it to curve around obstacles and fit into tight spaces, making it an adaptable choice for various pool designs.

- Application:

- Commonly used to connect pool filters, pumps, and skimmers, ensuring efficient water flow throughout your pool system. Its adhesive nature simplifies installation, as each connection point just requires the application of glue.

How are PVC sleeves used in pool piping systems?

Here’s how they are typically used:

- Connecting Pipes: PVC sleeves are essential for joining PVC pipes securely in pool systems. They offer a seamless connection, ensuring that water flows smoothly without leaks or interruptions.

- Managing Pressure: These sleeves are designed to handle specific pressure levels, often up to 10 bar, ensuring durability and stability within the piping system.

- Standard Sizes: Commonly, the outer diameter for these sleeves is around 50 mm, making them compatible with standard pool piping dimensions.

By providing a reliable connection and managing pressure effectively, PVC sleeves help maintain the efficiency and longevity of pool plumbing systems.

What is a bypass set and how is it used in pool piping?

Understanding a Bypass Set and Its Role in Pool Piping

A bypass set is an essential component for managing water flow in pool piping systems, especially when integrating external heating solutions, like heat pumps or solar heating systems.

What a Bypass Set Does

Primarily designed with high-quality plastic, the bypass set is perfect for swimming pools seeking to optimize water temperature through alternative heating methods. This includes using solar collectors, mats, or similar solar technologies.

Components of a Bypass Set

- 3-Way Valve: The heart of the system, this valve allows you to direct water flow precisely. It can be adjust to turn the flow on or off as needed.

- Hose Connectors and Clamps: These are critical for secure connections, ensuring no leaks compromise the system’s effectiveness.

- Teflon Tape: Ensures tight seals between threaded connections to prevent leaks.

- T-Piece: This component splits or combines water flow, aiding in the customization of the water routing within the pool system.

Installation and Use

The complete bypass set accommodates swimming pool hoses with diameters of 32mm or 38mm. Its installation may vary depending on the specific external heating setup, but generally, it allows for the integration of solar or heat pump systems with existing pool piping.

By adding a bypass set, pool owners can easily adjust water circulation, directing heated water from their chosen system back into the pool. This not only aids in maintaining a pleasant swimming temperature but also enhances the overall efficiency and effectiveness of the heating system.

Can a PVC pipe be glued into a transition fitting?

Yes, a PVC pipe can be glue into a transition fitting. To ensure a secure connection, you’ll need to follow a few steps. First, select a transition fitting that is compatible with PVC pipes.

Materials Required:

- PVC pipe

- Transition fitting

- PVC primer

- PVC cement

Step-by-Step Guide:

- Clean the Surfaces: Start by cleaning both the PVC pipe and the transition fitting. Any dirt, grease, or debris can hinder the bonding process.

- Apply PVC Primer: Use PVC primer to coat both the outside of the pipe and the inside of the fitting. This prepares the surfaces for a stronger bond.

- Apply PVC Cement: After priming, immediately apply PVC cement to the same areas. Be sure to apply an even layer.

- Join the Pieces: Push the pipe into the transition fitting with a twisting motion. Hold the connection for about 30 seconds to ensure the bond sets.

- Cure Time: Allow the joint adequate time to cure before using, usually 24 hours, but check the cement manufacturer’s guidelines for exact times.

Can a PVC adhesive hose be glued into Pvc piping parts?

follow these steps:

- Prepare the Hose:

- Begin by cutting the hose neatly. A clean, straight cut is essential to maximize the bonding surface.

- Remove any burrs from the edges to prevent hindrance in the sealing process.

- Thoroughly clean the cut end to eliminate dirt and debris.

- Apply the Adhesive:

- Apply a generous amount of PVC adhesive. It’s important to cover evenly to ensure a comprehensive seal. Brands like Oatey or Weld-On offer reliable options.

- Allow the adhesive a moment to become tacky. This increases the effectiveness of the bond.

- Use an Adapter if Needed:

- For a smoother process, consider using an adapter or screw connection. This can provide additional stability and ease during installation.

- Connect and Secure:

- Firmly insert the hose into the piping part, twisting slightly if necessary to spread the adhesive evenly.

- Hold the connection steady for a few seconds to ensure it sets properly.

What is the purpose of a pipe clamp in pool piping systems?

Understanding the Role of a Pipe Clamp in Pool Piping Systems

A pipe clamp is essential in securing pool piping systems. Designed to hold pipes firmly in place, it prevents movement and potential leaks in the system.

Key Benefits of Using Pipe Clamps:

- Stability and Support: Critical in maintaining the alignment of PVC pipes, particularly those with a standard external diameter, like 50 mm, commonly used in pool installations.

- Versatile for Different Pool Environments: Suitable for use in both chlorine and saltwater pools, ensuring consistent performance regardless of the water type.

- Durable Construction: Typically craft from high-quality materials such as robust plastic, these clamps are built to withstand harsh pool environments, resisting both chemical and physical wear.

In essence, pipe clamps are vital components that contribute to the longevity and efficiency of pool piping systems, ensuring a seamless flow of water without disruptions.

What safety precautions should be taken when using PVC solvent and adhesive?

by following

- Flammability Awareness: Both PVC solvent and adhesive are highly flammable. To avoid any risk of fire, ensure that your work area is free from open flames and other heat sources.

- Proper Ventilation: Conduct all cleaning and gluing tasks in a well-ventilated space. Good airflow is essential to disperse harmful fumes and reduce inhalation risk.

- Personal Protective Equipment (PPE): Always wear protective goggles to shield your eyes and a suitable breathing mask to prevent fume inhalation. This helps in safeguarding your respiratory system and eyes from potential harm.

- Storage Guidelines: Store these materials in a dry, frost-proof area with ample ventilation. Avoid placing them in direct sunlight to prevent degradation of the chemicals and reduce any flammability risk.

What can be done if connection hoses do not become tight and drip?

As Follows

- Check the Installation: First, ensure that the hoses are align correctly and fit snugly into their connections. Misalignment could cause them not to seal properly, leading to leaks.

- Apply Teflon Tape: Wrap Teflon tape (also known as plumber’s tape) around the threads of the affected connections. This tape acts as a sealant, helping to create a tighter fit and prevent leaks.

- Secure the Connections: Once the tape is apply, reconnect the hoses. Ensure they are screw on tightly, but be cautious not to over-tighten, which could damage the threads.

- Inspect for Damage: After applying the tape and securing the hoses, look for any signs of wear or damage, such as cracks or splits in the hoses that might require replacement.

What is the external diameter typically used for private pool fittings?

For private pool fittings, the standard external diameter commonly utilized is 50 millimeters (OD 50).

What is a PVC transition angle for adhesive PVC hoses?

A PVC transition angle is an essential plumbing component designed to connect adhesive PVC hoses at a 90-degree angle, providing a seamless directional change in the system. This angle elbow, crafted from high-quality plastic, ensures durability and flexibility in various settings.

Key Features

- Material: Constructed from robust PVC material, renowned for its resistance to both chlorine and saltwater environments.

- Compatibility: Specifically used with adhesive PVC hoses, making them suitable for swimming pools and other water systems.

- Technical Specifications: Typically available with dimensions like a 50 mm outer diameter (DA 50) and a compatible 50 mm clamp size (d 50), offering a precise fit for secure connections.

Whether you’re integrating it into a home pool setup or a larger water management system, this PVC transition angle is design to provide reliable performance and ease of installation.

What is the purpose a PVC insert with a thread in systems?

Let’s explore how it functions and why it’s essential:

- Connection and Compatibility: This component features a threaded interior, making it perfect for securely attaching pipes and other fittings within pool systems. Its design ensures that any connection is both dependable and watertight.

- Versatile Use with Water Types: Whether your pool uses chlorine or salt water for sanitation, this insert is built to resist corrosion. This makes it a versatile choice for different water environments without worrying about durability or chemical damage.

- Size and Specifications: Typically, these inserts have an outer diameter of 50 mm, coupled with a 3/4 inch inner thread. This specification allows it to seamlessly integrate into various plumbing setups commonly found in both residential and commercial pools.

- Maintaining System Integrity: By providing a robust connection point, a PVC insert helps maintain the integrity of your pool’s plumbing system. This not only ensures efficient water circulation but also minimizes the risk of leaks.

What is a PVC reduction angle and where is it used?

A PVC reduction angle, commonly referred to as a 90-degree elbow reducer, is a plumbing fitting designed to connect pipes of different diameters at a right angle. This component is integral in directing water flow within piping systems while smoothly transitioning between varying pipe sizes.

Composition and Durability

Crafted from robust, high-quality PVC (polyvinyl chloride), these reducers are resilient and suitable for various environments. Notably, they perform exceptionally well in both chlorinated and saltwater systems, making them ideal for applications that demand high resistance to corrosion and chemical exposure.

Applications

PVC reduction angles are most frequently useful in the following settings:

- Swimming Pools: They facilitate the circulation of water by effectively managing the flow through filtration systems.

- Irrigation Systems: These angles connect pipes of different diameters, ensuring efficient water distribution across agricultural fields.

- Aquarium Plumbing: Essential for maintaining a safe and functional aquatic environment by managing water flow and pressure.

Technical Specifications

The fittings often accommodate a permissible operating pressure of up to 16 bar (PN 16), supporting robust operations across various applications. Typical dimensions include outer diameters such as 40/50 x 50 mm, allowing for versatile integration within existing piping infrastructures.

By using PVC reduction angles, you can achieve reliable connections and efficient flow management across diverse water-based systems.

Why is the 3-way valve from a bypass set stiff when used for the first time?

If you’ve encountered stiffness in your 3-way valve during its initial use, you’re not alone. This common issue stems from the internal components and the way they’re designed to function.

The Role of Lubrication

Inside the valve, seals are coat with a lubricant. This serves a dual purpose:

- Sealing: The lubricant ensures a tight seal, preventing leaks.

- Ease of Adjustment: It helps the components glide against each other, typically made of plastic, facilitating smoother operation over time.

The Break-In Period

During the first few adjustments, the lever might feel tight due to the fresh lubricant settling into place. Rest assured, this is typical. After a few turns, you should notice the valve operating more smoothly as the lubricant fully distributes and the components wear in slightly.

What to Expect

- Initial firmness is normal—don’t force it; gentle, gradual turns are effective.

- Improved operation with use—after several cycles, the valve should move more freely.

If persistent stiffness continues, consider consulting the manufacturer’s guidelines or seeking professional assistance to ensure everything is functioning as it should.

What is the function of a PVC transition fitting AG for adhesive PVC hoses?

A PVC transition fitting AG serves as a crucial component when working with adhesive PVC hoses. It’s craft from durable, high-quality plastic, ensuring a long-lasting solution for diverse plumbing needs.

Key Functions:

- Compatibility with Various Pool Systems: This fitting is designed for pools utilizing both chlorine and saltwater systems, making it versatile for different maintenance setups.

- Connection and Adaptation: It effectively connects PVC hoses with other plumbing components, ensuring a secure and leak-proof joint. The fitting typically features a d 50 clamp that transitions to a 1 1/2 inch external thread, allowing for easy integration with diverse equipment.

- Durability and Reliability: The high-quality material ensures the fitting withstands harsh environmental conditions, including exposure to chemicals like chlorine and salt, commonly found in pool settings.

What is the function of a PVC transition fitting lG for adhesive PVC hoses?

Here’s how it functions:

- Adaptability: This fitting is specifically designed to join an adhesive PVC hose to other plumbing parts seamlessly. It ensures compatibility across various piping setups, crucial for maintaining your pool’s operational integrity.

- Material Suitability: Constructed from high-quality plastic, it is robust and durable, making it ideal for pools treated with both chlorine and salt water. This versatility means it can withstand harsh chemical conditions commonly found in pool environments.

- Technical Specifications: The fitting often features dimensions such as a 50mm clamp alongside a 1 1/2 inch internal thread, guaranteeing it fits snugly with other standardized pool piping components. This precise measurement ensures a leak-proof connection, preserving the water system’s efficiency.

What is a PVC transition screw joint glued sleeve?

A PVC transition screw joint glued sleeve is a versatile plumbing component designed to connect pipes securely. This particular fitting is craft from high-quality PVC plastic, making it durable and resistant to harsh elements such as chlorine and salt water, which are common in pool and marine environments.

Key Features:

- Material: Constructed from robust PVC, which ensures longevity and resistance to chemical corrosion.

- Pressure Rating: Capable of handling a nominal pressure of up to 16 bar (PN 16), making it suitable for a variety of high-pressure applications.

- Dimensions: Typically available with an outer diameter of 40/50 mm.

- Thread Specifications: Incorporates a 1 1/2 inch female thread, which facilitates easy integration with other plumbing components.

This fitting is essential for anyone needing a reliable connection in a fluid system, ensuring a leak-proof, secure joint between pipes. Whether you’re working on a swimming pool or an industrial scale water system, a PVC transition screw joint glued sleeve offers a practical and effective solution.

What is a PVC transition fitting sleeve for adhesive PVC hoses?

Understanding PVC Transition Fitting Sleeves for Adhesive PVC Hoses

A PVC transition fitting sleeve serves as a connector specifically designed for use with adhesive PVC hoses. This fitting, crafted from durable plastic, ensures a secure and seamless connection between different sections of PVC hose, making it an essential component for various applications.

Key Features

- Material Quality: Constructed from high-grade plastic, these sleeves offer excellent strength and durability, suitable for long-term use.

- Compatibility: Designed for systems like swimming pools, these fittings are compatible with both chlorine-treated and saltwater environments, enhancing their versatility in different settings.

- Specifications: A typical configuration includes measurements like 50mm outer diameter adhesive sockets, ensuring they fit standard hose sizes securely.

Applications

Ideal for both residential and commercial pool setups, these fittings maintain the integrity of water flow systems, preventing leaks and ensuring smooth transitions between different hose sections. Whether you’re assembling a new pool system or upgrading an existing setup, a PVC transition fitting sleeve is a vital tool for reliable construction and maintenance.

What is the purpose of a PVC transition screw connection adhesive sleeve?

A PVC transition screw connection adhesive sleeve with a male thread serves a crucial role in plumbing and piping systems. Its primary purpose is to facilitate the seamless connection between different pipe components, ensuring a strong and watertight seal.

Key Features and Benefits:

- Durability: Crafted from high-quality plastic, these sleeves are design to endure harsh conditions. They’re resistant to both chlorine and salt water, making them suitable for varied environments, including swimming pools and marine applications.

- Pressure Handling: Capable of withstanding pressures up to 16 bar (PN 16), these sleeves are reliable for high-pressure applications, ensuring secure connections without leaks.

- Design Specifications: The sleeve typically features an outside diameter of 50 mm and a 1 1/2 inch male thread. This specification allows it to fit a wide range of piping systems and components.

- Sealing Efficiency: An included O-ring enhances the connection’s integrity, providing additional assurance against leaks by forming a perfect seal.

What is a PVC transition sleeve nipple and how is it used?

A PVC transition sleeve nipple is a versatile plumbing component commonly used in pool systems. Its primary purpose is to connect two pipes or fittings, facilitating a seamless transition in various water-based setups.

Key Features

- Diameter and Threading: Typically, these nipples have an outer diameter of 50 mm, complemented by a 2-inch female thread. This specific design makes them suitable for a broad range of applications.

- Material Suitability: Made from durable PVC, these sleeves are ideal for environments that include both chlorine and salt water—common substances in swimming pool systems.

- Pressure Capacity: They can withstand pressures up to 10 bar (also known as PN 10), ensuring reliability under standard operating conditions.

Applications

- Swimming Pools: Use them to connect pipes within pool filtration systems, especially when transitioning between different pipe sizes or materials.

- Water Treatment: Effective in systems where clean, non-corrosive, and chemical-resistant connections are essential.

How does a PVC screw connection gluing sleeve function?

Here’s how it functions:

- Connecting Components: This sleeve is designed to seamlessly connect two PVC pipes or fittings. It can be glue to the screw connection on both ends, ensuring a secure and leak-proof joint.

- Material and Durability: Crafted from high-quality plastic, these sleeves are built to withstand diverse chemical environments. They’re commonly useful in pools due to their resistance to both chlorine and salt water, preventing corrosion or deterioration over time.

- Pressure and Dimension: With the capability to handle operating pressures up to 16 bar (equivalent to PN 16 rating), these sleeves are suitable for high-pressure applications. Typically, they have an outer diameter of 50 mm, aligning with standard pool piping sizes for easy integration.

In summary, a PVC screw connection gluing sleeve is essential for creating durable and reliable connections in pool systems. It’s engineered to withstand specific environmental and pressure demands, making it an indispensable component.

How do you connect two lNTEX floating hoses with a 2″ external thread?

As Follows

- Gather Materials:

- Start with two 2″ double nipples, which are essential connectors for this task.

- Acquire flat gaskets to ensure a tight seal between the connections.

- Preparation:

- Begin by inspecting the ends of the hoses for any debris or damage. Clean them if needed to ensure optimal connectivity.

- Assembly:

- Insert one end of the first hose onto one side of the double nipple, making sure it’s snug and properly aligned.

- Place a flat gasket inside the hose end to prevent leaks once tightened.

- Connection:

- Repeat the process for the other hose by attaching it to the opposite end of the double nipple.

- Again, ensure that a flat gasket is in place before securing the connection.

- Tightening:

- Tighten the hoses firmly onto the double nipple. Hand-tightening is usually sufficient, but you can use a wrench for a more secure fit if necessary.

- Leak Check:

- Once both hoses are connect, check for leaks by running water through the hoses. Adjust the connections if needed to eliminate any drips.